Pioneering Progress in Magnetic Tooling and Intelligent Manufacturing #

Since 1988, Earth-Chain Enterprise Co., Ltd. has dedicated itself to advancing magnetic tool technology, consistently achieving global patents and industry recognition. Our commitment to innovation has positioned us at the forefront of intelligent manufacturing, with a focus on integrating automation, digitalization, and smart production systems.

2024: Advancing Digital and Smart Manufacturing #

- Secured subsidies from the Industrial Development Administration and the Industrial Development Bureau, Ministry of Economic Affairs, under the Digital Manufacturing Management Value-Added Program and the Smart Machinery Academia-Industry Collaboration Subprogram.

2023: Embracing Low-Carbon and Smart Upgrades #

- Received funding from the Ministry of Economic Affairs (MOEA) for the Low-Carbon and Smart Upgrade Transformation Program, targeting small and medium-sized manufacturing enterprises.

- Awarded a subsidy from the Department of Industrial Technology (DoIT), MOEA, through the CITD Industrial Technology Program for the project: “Development of a Reverse-Sequence Demagnetization Controller for Permanent Electro-Magnetic Chucks.”

- Supported by the Smart Machinery Academia-Industry Collaboration Program, sponsored by the Industrial Development Administration (IDA), MOEA.

- Achieved new patents in Taiwan and China for the linear-type permanent electro-magnetic chuck and circuit system, as well as for the permanent electro-magnetic chuck with clamping-jaw positioning and zoned magnetic force control.

- Introduced an APS (Advanced Planning & Scheduling) digital lean pre-scheduling system, integrated with a smart dashboard for visualized production data analysis. This system enables real-time monitoring of raw material supply, dynamic work order assignment, and full visibility of production line status, reducing inventory and lead times for customized products. The result is a smart, lean, and fully integrated intelligent manufacturing facility.

2022: Smart Magneto-Automated Factory Expansion #

- Awarded a grant under the “Digital Lean Management (TPS) Subsidy Program” by the Industrial Technology Research Institute (ITRI).

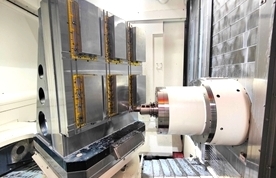

- Expanded the Smart Magneto-Automated Factory, integrating CNC intelligent precision machine tools with advanced magnetic tooling applications.

- Acquired a Japanese-made Mazak horizontal machining center with a 6-pallet changer and implemented FANUC robotic arms for a fully automated production line.

- Developed custom magnetic fixtures for robotic arms, combined with a multi-zone collaborative magnetic clamping system, enabling 48-hour unmanned, lights-out production.

- Achieved a 2.5x increase in process efficiency, expanded global market share, and strengthened internal R&D for innovative, high-value solutions.

- Became the first professional demonstration factory in Taiwan—and potentially worldwide—specializing in magnetic tooling applications.

2021: Intelligent Plant Rebuild #

- Applied core knowledge to rebuild the plant with an intelligent IOMM (Internet of Machine and MagVise) system, achieving excellent production efficiency and product quality.

2019: Permanent Electro-Magnet for Automation #

- Developed a permanent electro-magnet, applied with robot arms for automatic production and transport lines in medical equipment, machinery, and laboratory equipment.

- The permanent magnetic structure ensures workpiece safety even during power failures, enabling reliable clamp and de-clamp processes.

2018: Industry 4.0 and Modular Electromagnets #

- Collaborated with leading domestic manufacturers to plan automation and intelligent production for Industry 4.0 demands.

- Developed the ECM Series electromagnets for automatic robotic arms, featuring modular design.

2017: Advanced Magnetic Chucks #

- Developed the EEPM-A/EEPM-CIRA/EEPM-CIRSA Series of electro-permanent magnetic chucks (cubic pole 35mm square) for thin, small workpiece machining.

2016: Battery-Powered Lifting Magnets and ISO Certification #

- Introduced the EPLM(B) Series electro-permanent lifting magnets (battery type) for moving large iron and steel plates, both indoors and outdoors. The lithium battery design requires no power supply to maintain the magnetic state.

- Achieved ISO9001:2015 certification from UKAS.

2015: ELM Series Improvements and HMI Integration #

- Enhanced the ELM permanent lifting magnet series with a new nickel-plated design to prevent paint peeling and ensure product longevity. Applied for a design patent to protect customer rights.

- Expanded universal voltage compatibility and developed a human-machine interface (HMI) touch screen system for operational feedback.

2014: Quick Mold Change System Launch #

- Launched the EEPM-PIM Series electro-permanent magnetic chuck for quick mold change systems in plastic injection machines at TAIPEI PLAS 2014, with live demonstrations alongside Victor Taichung, Chen Hsong Group, and Fu Chun Shin Group.

2013: Excellence Awards and ERP Implementation #

- Received the 21st Taiwan Excellence Award for the EEPM-C Series.

- Implemented ERP systems to optimize resource allocation and improve efficiency.

- Developed the EEPM-PIM Series for plastic injection machines, featuring super power magnetic force (1250kgf/100cm2, 4 pole).

- Honored with the Golden Hand Award for outstanding SMEs.

2012: Innovation Award #

- Received the 19th Taiwan SMEs Innovation Award for the EEPM-C Series.

2011: Patented Magnetic Chucks for Precision Applications #

- Developed the EEPML Series electro-permanent magnetic chucks for linear guideways and high-precision oblong workpiece machining, acquiring a Taiwan patent.

- Developed the EEPM-C Series for vertical lathes, CNC machining centers, and double column machining centers, with patents in Taiwan and China and applications in the USA, Japan, Korea, Germany, and Italy.

2009: Excellence and Good Design Recognition #

- New products received the 18th Taiwan Excellence qualification and Good Design Product qualification.

2008: International Patents for MagVise Series #

- Focused on R&D for products like the MagVise Magnetic Workholding Electro-Permanent Magnetic Chuck EEPM-CIR and EEPM-CIT Series, acquiring patents in the USA, Germany, Japan, Korea, China, and Taiwan.

2007: Product Integration and Market Expansion #

- Integrated related product series, introducing MagVise Workholding products for vertical and horizontal CNC machining centers, milling machines, and vertical lathes. This innovation transformed traditional metalworking clamping methods and accelerated sales growth.

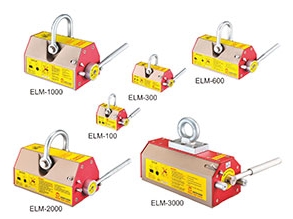

- Received the 16th Taiwan Excellence qualification for the ECB Series and Good Design Product qualification for the ELM Series.

2006: EEPM Series and Factory Expansion #

- Developed the EEPM Series electro-permanent magnetic chucks and expanded the factory in Wu-Chi Industry Park.

- Began operations in the new facility in March, introduced a quality management system, and received ISO9001:2000REV certification from UKAS.

- Awarded Good Design Product qualification for the EEPM Series.

2005: ECB Series and SBIR Project #

- Developed the ECB Series and passed the SBIR (Small Business Innovation Research) project by the Department of Industrial Technology, receiving a two million New Taiwan Dollar reward.

- Acquired ECB Series patents in the USA, Germany, Italy, Japan, Korea, China, and Taiwan.

2004: Product Development and ELM Series Patents #

- Invested in human and material resources to develop multiple product series, acquiring two patents for the ELM permanent lifting magnet series.

2002: Patents for Clamping Block and ECB Series #

- Developed and patented the Permanent Magnetic Clamping Block and ECB Series.

1998: Magnetic Base and V-Block Series #

- Continued development of magnetic base and magnetic V-Block series.

1995: ELM Series Patents and Global Branding #

- Developed and patented two ELM permanent lifting magnets, establishing the brand for global markets. Began participating in international machine tool exhibitions and focused on the machine tool market.

1994: Relocation and OEM Collaboration #

- Moved to Shalu Town, Taichung, and began OEM collaboration with a renowned Japanese enterprise in magnetic tools. Initiated in-house R&D and manufacturing of magnetic tools.

1988: Company Founding and Early Innovations #

- Founded by Mr. Richard Wang in Chingshuei Town, initially focusing on OEM metal parts manufacturing.

- Secured patents for a hydraulic vise with lever type in 1990 and 1992.

Ready to optimize your projects with advanced magnetic technologies? Get In Touch Today!