Advanced Magnetic De-burring & Polishing: Technology, Models, and Applications #

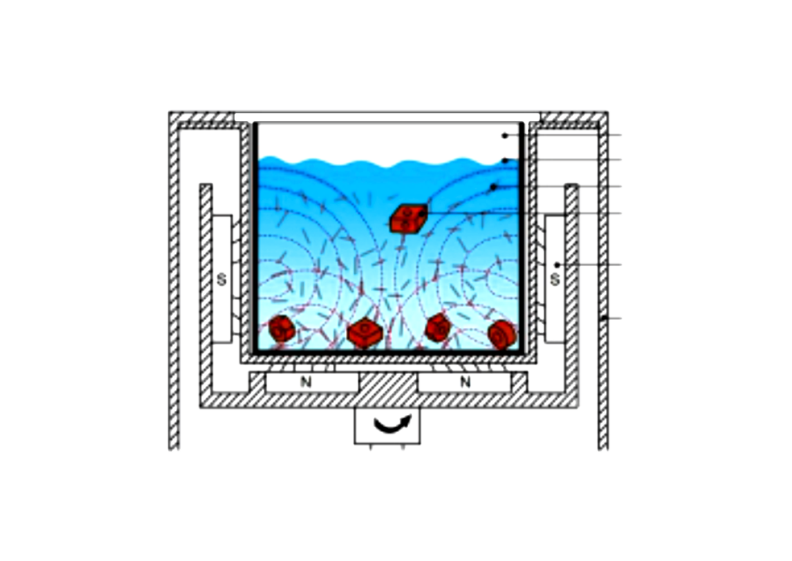

Magnetic de-burring and polishing machines utilize patented magnetic field technology to induce rapid rotation of stainless steel media (pins), enabling efficient grinding, de-burring, polishing, and cleaning of workpieces. This approach is especially effective for intricate parts, including holes, seams, concave right angles, threads, and other fine features, delivering results in just 5 to 20 minutes.

Product Range Overview #

Standard Model (Apply to Metal Parts)

Standard Model (Apply to Metal Parts)

HD-716 (0.2 KG grinding capacity)

HD-716 (0.2 KG grinding capacity)

HD-728 (1 KG grinding capacity)

HD-728 (1 KG grinding capacity)

HD-735 (3 KG grinding capacity)

HD-735 (3 KG grinding capacity)

HD-745 (5 KG grinding capacity)

HD-745 (5 KG grinding capacity)

HD-750 (8 KG grinding capacity)

HD-750 (8 KG grinding capacity)

HD-765 (12 KG grinding capacity)

HD-765 (12 KG grinding capacity)

HD-768 (12 KG grinding capacity)

HD-768 (12 KG grinding capacity)

HD-790 (18 KG grinding capacity)

HD-790 (18 KG grinding capacity)

HD-765F (12 KG grinding capacity)

HD-765F (12 KG grinding capacity)

HD-790F (18 KG grinding capacity)

HD-790F (18 KG grinding capacity)

HD-7150 (8 KG grinding capacity)

HD-7150 (8 KG grinding capacity)

HD-7165 (12 KG grinding capacity)

HD-7165 (12 KG grinding capacity)

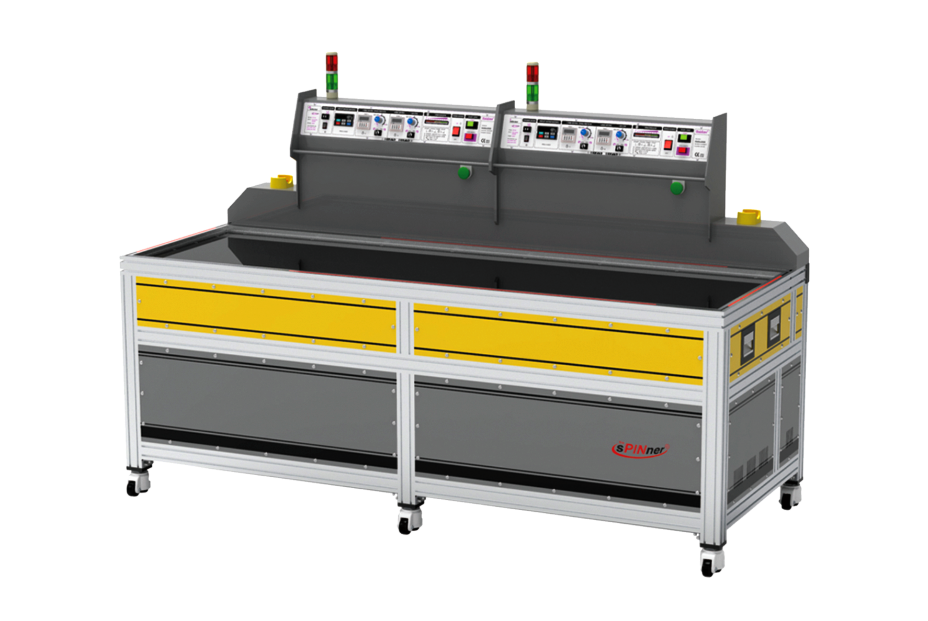

HD-7200 (Twin-spindle & Horizontally movement)

HD-7200 (Twin-spindle & Horizontally movement)

HD-7250 (16 KG grinding capacity)

HD-7250 (16 KG grinding capacity)

HD-7265 (24 KG grinding capacity)

HD-7265 (24 KG grinding capacity)

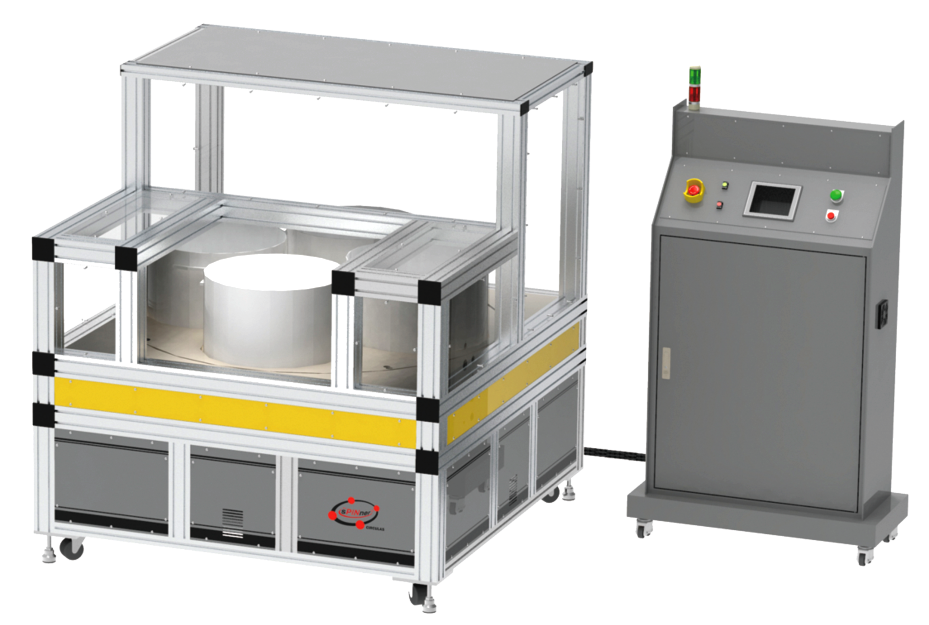

HD-7335 (Triple Spindle & multifunction)

HD-7335 (Triple Spindle & multifunction)

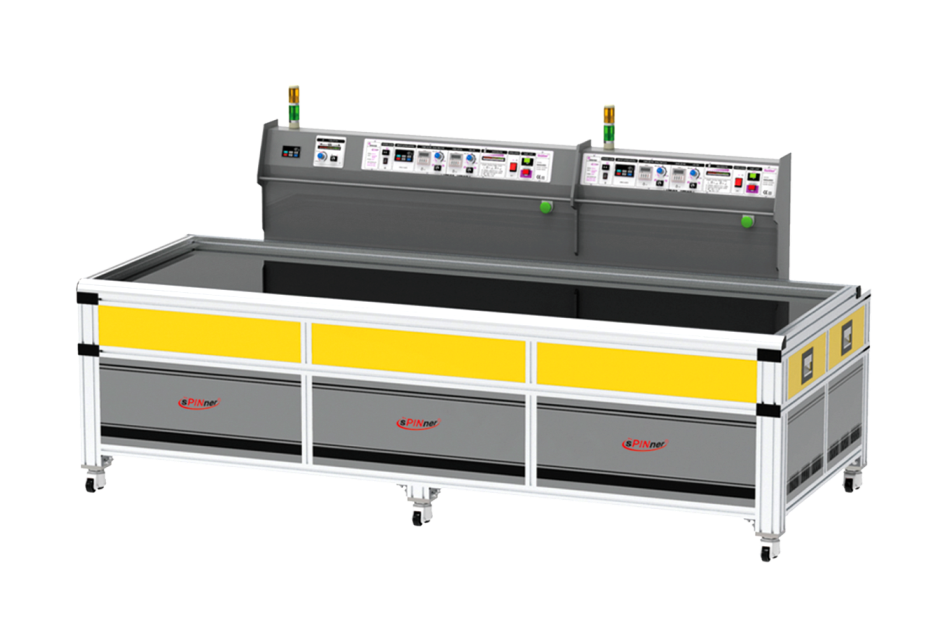

HD-7400 (TWIN-ENGINE: Twin-spindle & Horizontally movement)

HD-7400 (TWIN-ENGINE: Twin-spindle & Horizontally movement)

HD-717(HD-727) (Powerful Bubble Wash Machine)

HD-717(HD-727) (Powerful Bubble Wash Machine)

HD-712 (Magetic Pins Separator)

HD-712 (Magetic Pins Separator)

HD-7445 (1 tank: 5KG, 4 tanks: 20KG)

HD-7445 (1 tank: 5KG, 4 tanks: 20KG)

HD-7450C (1 tank: 8KG, 4 tanks: 32KG)

HD-7450C (1 tank: 8KG, 4 tanks: 32KG)

HD-7645C (1 tank: 5KG, 6 tanks: 30KG)

HD-7645C (1 tank: 5KG, 6 tanks: 30KG)

Key Features and Advantages #

- Utilizes innovative and patented magnetic field technology for high-speed, efficient grinding.

- Patented grinding pins are effective for holes, seams, concave right angles, threads, and other fine workpiece features.

- Achieves de-burring, polishing, cleaning, and grinding in a single process, typically within 5 to 20 minutes.

- Removes oxide films, sintering, and tool marks; also suitable for rubber and plastic de-burring, joint line removal, and increasing surface hardness on copper.

- Specially designed for irregular-shaped parts, ensuring simultaneous de-burring, polishing, cleaning, and grinding.

- High-speed operation, easy and safe to use, with no consumables required and low operational cost.

- Maintains workpiece integrity: does not deform, damage, or affect the precision of the workpiece surface.

Applications #

- CNC lathe-processed parts

- Aluminum and zinc die-cast parts

- Precision stamping parts

- Precision springs and spring bands

- Aerospace and medical equipment components

- Electronic components

Optional Accessories and Consumables #

For further details, practical cases, and videos, please visit the Earth-Chain Magnetic De-burring & Polishing Machine page.

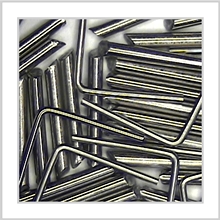

A1 Grinding Material

A1 Grinding Material A2 The slurry

A2 The slurry A3 Accessories

A3 Accessories