Streamlining Mold Changes in Plastic Injection Molding #

Modern manufacturing demands efficiency, safety, and precision—especially in plastic injection molding. Quick mold change systems have become essential for reducing downtime and increasing productivity. At the forefront of this innovation are magnetic workholding solutions, which offer a reliable and rapid method for securing molds during changeovers.

Magnetic Workholding for Quick Mold Change #

Magnetic workholding systems utilize powerful electro-permanent magnets to securely clamp molds in place. This technology eliminates the need for traditional mechanical clamps, reducing manual labor and minimizing the risk of human error. The result is a safer, faster, and more consistent mold change process.

EEPM-PIM Series: A Closer Look #

The EEPM-PIM Series is specifically engineered for plastic injection machines, providing a robust solution for quick mold changes. This series leverages advanced magnetic technology to ensure:

- Rapid Mold Changeover: Significantly reduces the time required to switch molds, supporting high-mix, low-volume production environments.

- Enhanced Safety: The magnetic system maintains a secure hold on the mold, even in the event of power loss, ensuring operator safety.

- Uniform Clamping Force: Distributes clamping force evenly across the mold surface, minimizing deformation and improving product quality.

- Simple Operation: Intuitive controls make the system easy to use, reducing training requirements and operator fatigue.

Advantages of Magnetic Quick Mold Change Systems #

- Increased Productivity: Faster mold changes mean less downtime and more production cycles.

- Reduced Maintenance: Fewer moving parts compared to mechanical clamping systems result in lower maintenance needs.

- Versatility: Suitable for a wide range of mold sizes and shapes, accommodating diverse production requirements.

- Energy Efficiency: Electro-permanent magnets require power only during activation and deactivation, minimizing energy consumption during operation.

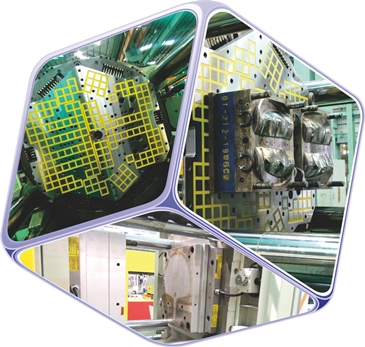

Product Gallery #

Learn More #

For detailed specifications, application examples, and further information about the EEPM-PIM Series and other magnetic workholding solutions, visit the official product page.

Contact Information:

- Phone: +886-4-2630-3737

- Fax: +886-4-2630-3636

- Email: ece@earth-chain.com.tw

- Address: No.551, Sec. 1 Gangbu Rd., Wu-Chi, Taichung 43546, Taiwan (R.O.C)

- Website: www.earth-chain.com

Quick Mold Change Systems for Plastic Injection Machine EEPM-PIM SERIES

Quick Mold Change Systems for Plastic Injection Machine EEPM-PIM SERIES