Applications of Magnetic Workholding and Automation Solutions

Table of Contents

Discover Real-World Applications of Magnetic Technologies #

Earth-Chain Enterprise Co., LTD. offers a diverse range of magnetic workholding and automation solutions, designed to optimize manufacturing processes across various industries. Below is an organized overview of practical application cases, each demonstrating the versatility and effectiveness of our technologies in real-world scenarios.

Application Categories #

Automated Production Applications

Automated Production Applications

Precision Grinding Applications

Precision Grinding Applications

Vertical Machining Applications

Vertical Machining Applications

Horizontal Machining Applications

Horizontal Machining Applications

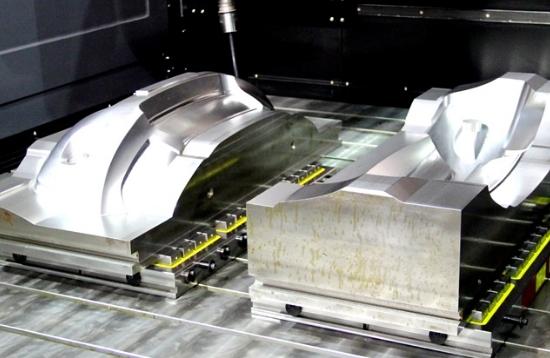

Double Column Machining Applications

Double Column Machining Applications

Customization Applications

Customization Applications

Round Workpieces Machining Applications

Round Workpieces Machining Applications

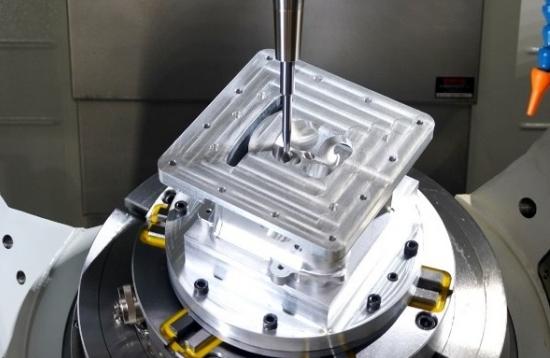

4 Axis Machining Applications

4 Axis Machining Applications

Linear Grinding Applications

Linear Grinding Applications

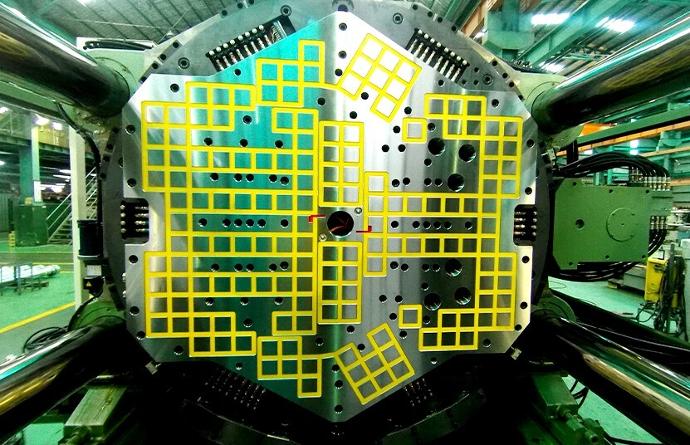

Quick Mold Changing Applications

Quick Mold Changing Applications

Rail Machining Applications

Rail Machining Applications

Multi-Pallet Machining Applications

Multi-Pallet Machining Applications

Ready to Optimize Your Projects? #

If you are interested in enhancing your manufacturing processes with advanced magnetic technologies, get in touch today!

Explore More:

Contact Information:

- Address: 551, Sec. 1 Gangbu Rd., Wu-Chi, Taichung 43546 , Taiwan (R.O.C)

- Email: ece@earth-chain.com.tw

- Tel: +886-4-2630-3737

- Fax: +886-4-2630-3636