Unlocking Efficiency in 4-Axis CNC Machining #

The integration of advanced workholding solutions is essential for maximizing the potential of 4-axis CNC machining. The EEPM-CIT Series Electro-Permanent Magnetic Chuck is engineered to provide unobstructed cutter movement and full utilization of CNC 4-axis index device functions, supporting a wide range of machining applications.

EEPM-CIT Series: Electro-Permanent Magnetic Chuck #

The EEPM-CIT Series is specifically designed to be used in combination with CNC 4-axis index devices, offering robust magnetic clamping for both magnetic and non-magnetic workpieces. This system ensures secure holding power and operational flexibility, making it suitable for various machining requirements.

Key Features #

- Exceptional Magnetic Force: Delivers a super power magnetic force of 1250kgf/100cm² ±5% (4 Poles), ensuring reliable workpiece retention during machining.

- Independent Face Control: Each working face can be controlled independently for ON and OFF states, allowing for efficient loading and unloading of workpieces. Switching between power states takes just 3 seconds.

- Versatile Configurations:

- EEPM-CIT2F: Features 2 magnetic working faces, enabling the clamping of two workpieces simultaneously. Ideal for larger workpieces.

- EEPM-CIT2F2T: Combines 2 magnetic working faces with 2 T-slot working faces, supporting both magnetic and non-magnetic materials. Suitable for smaller workpieces.

- EEPM-CIT4FT: Offers 4 magnetic working faces with T-slots, optimized for smaller workpieces and increased flexibility.

- Unobstructed Machining: The design eliminates any obstruction to cutter movement, allowing full use of all CNC 4-axis index device functions.

Technical Specifications #

| Model | Dimension (mm) | Pitch (mm) | Pole Size (mm) | No. of Poles | Total Holding Power (kgf ±5%) | Chuck Net Weight (kg) | Voltage (Single Phase) | Current (A) | Controller |

|---|---|---|---|---|---|---|---|---|---|

| EEPM-CIT2F | 300×570 | 10 | 50×50 | 32×2 | 10,000 | 141 | DC220V (Controller AC220V/480V) | 30 | C2-2C1-G |

| EEPM-CIT2F2T | 240×570 | 10 | 50×50 | 24×2 | 7,500 | 228 | DC220V (Controller AC220V/480V) | 23 | C2-2C1-G |

| EEPM-CIT4FT | 240×570 | 10 | 50×50 | 16×4 | 5,000 | 219 | DC220V (Controller AC220V/480V) | 20 | C4-4C1-G |

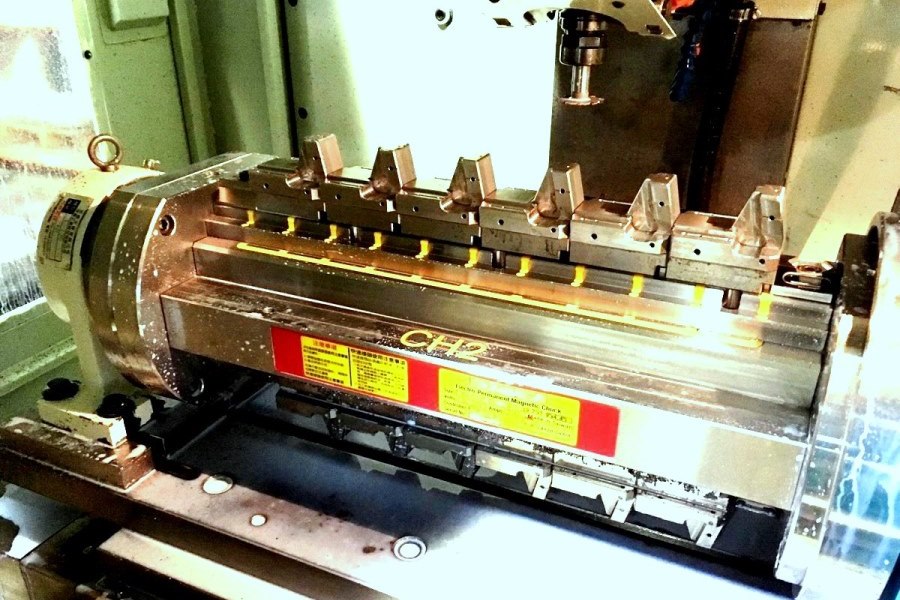

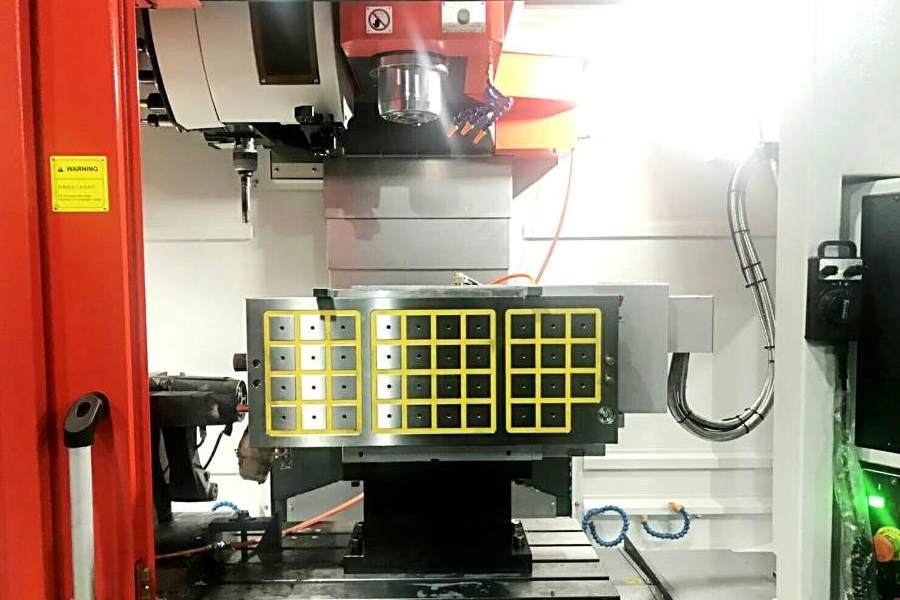

Practical Applications #

The following gallery showcases real-world use cases of the EEPM-CIT Series in 4-axis machining environments, highlighting its versatility and effectiveness in various setups:

For more information or to discuss how magnetic technologies can optimize your machining projects, get in touch today!