Innovative Workholding for 5-Axis CNC Machining #

Electro-permanent magnetic chucks, such as the EEPM-CIR and EEPM-CIRS Series, are transforming the landscape of 5-axis CNC machining. These advanced workholding solutions are designed to meet the demands of complex machining tasks, offering secure clamping, high accuracy, and operational efficiency.

Key Features and Benefits #

- Versatile Clamping: Suitable for a wide range of workpiece shapes and sizes, especially round and irregular forms often encountered in 5-axis operations.

- Enhanced Accessibility: Magnetic chucks provide unobstructed access to multiple sides of the workpiece, enabling efficient multi-face machining without frequent repositioning.

- Precision and Stability: The electro-permanent technology ensures consistent holding force, minimizing vibration and movement during high-speed machining.

- Operational Efficiency: Quick setup and release reduce downtime, supporting higher productivity in demanding manufacturing environments.

Practical Applications #

Electro-permanent magnetic chucks are particularly effective in industries requiring intricate machining, such as aerospace, automotive, and mold making. Their ability to securely hold components during complex tool paths makes them an essential asset for modern CNC 5-axis machining centers.

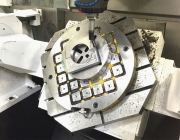

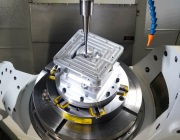

Visual Case Studies #

Below are practical examples showcasing the application of EEPM-CIR/EEPM-CIRS Series magnetic chucks in real-world 5-axis CNC machining scenarios:

CNC 5 Axis Machining Example 1

CNC 5 Axis Machining Example 1

CNC 5 Axis Machining Example 2

CNC 5 Axis Machining Example 2

CNC 5 Axis Machining Example 3

CNC 5 Axis Machining Example 3

CNC 5 Axis Machining Example 4

CNC 5 Axis Machining Example 4

CNC 5 Axis Machining Example 5

CNC 5 Axis Machining Example 5

CNC 5 Axis Machining Example 6

CNC 5 Axis Machining Example 6

CNC 5 Axis Machining Example 7

CNC 5 Axis Machining Example 7

CNC 5 Axis Machining Example 8

CNC 5 Axis Machining Example 8

CNC 5 Axis Machining Example 9

CNC 5 Axis Machining Example 9

For more detailed product information, visit the EEPM Series for Vertical Lathe Center page.