Advanced Magnetic Workholding for CNC Vertical Machining Centers #

Magnetic workholding technology plays a crucial role in enhancing the efficiency and precision of CNC vertical machining centers. This article presents an organized overview of three main magnetic workholding solutions, each designed to meet specific machining requirements and improve operational productivity.

Available Magnetic Workholding Solutions #

Three primary models are available for CNC vertical machining centers:

- Electro-Permanent Magnetic Chuck EEPM Series

- Electro-Permanent Magnetic Chuck-Connection Type EEPM-C Series

- Permanent Magnetic Clamping Block ECB Series

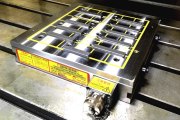

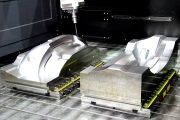

Electro-Permanent Magnetic Chuck EEPM Series #

The EEPM Series is engineered for robust and reliable workpiece clamping, ensuring high accuracy and repeatability in CNC vertical machining operations. This series is suitable for a wide range of workpiece sizes and shapes, providing strong holding force and easy operation.

EEPM Series Example 1

EEPM Series Example 1

EEPM Series Example 2

EEPM Series Example 2

EEPM Series Example 3

EEPM Series Example 3

EEPM Series Example 4

EEPM Series Example 4

EEPM Series Example 5

EEPM Series Example 5

EEPM Series Example 6

EEPM Series Example 6

EEPM Series Example 7

EEPM Series Example 7

EEPM Series Example 8

EEPM Series Example 8

EEPM Series Example 9

EEPM Series Example 9

EEPM Series Example 10

EEPM Series Example 10

EEPM Series Example 11

EEPM Series Example 11

EEPM Series Example 12

EEPM Series Example 12

EEPM Series Example 13

EEPM Series Example 13

EEPM Series Example 14

EEPM Series Example 14

EEPM Series Example 15

EEPM Series Example 15

EEPM Series Example 16

EEPM Series Example 16

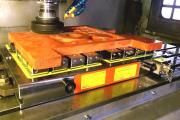

Electro-Permanent Magnetic Chuck-Connection Type EEPM-C Series #

The EEPM-C Series offers a connection-type design, providing flexibility and adaptability for various workpiece configurations. This series is ideal for setups requiring modularity and quick changeovers.

EEPM-C Series Example 1

EEPM-C Series Example 1

EEPM-C Series Example 2

EEPM-C Series Example 2

EEPM-C Series Example 3

EEPM-C Series Example 3

EEPM-C Series Example 4

EEPM-C Series Example 4

EEPM-C Series Example 5

EEPM-C Series Example 5

EEPM-C Series Example 6

EEPM-C Series Example 6

EEPM-C Series Example 7

EEPM-C Series Example 7

EEPM-C Series Example 8

EEPM-C Series Example 8

EEPM-C Series Example 9

EEPM-C Series Example 9

EEPM-C Series Example 10

EEPM-C Series Example 10

EEPM-C Series Example 11

EEPM-C Series Example 11

EEPM-C Series Example 12

EEPM-C Series Example 12

EEPM-C Series Example 13

EEPM-C Series Example 13

EEPM-C Series Example 14

EEPM-C Series Example 14

EEPM-C Series Example 15

EEPM-C Series Example 15

EEPM-C Series Example 16

EEPM-C Series Example 16

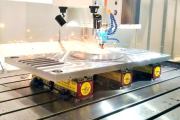

Permanent Magnetic Clamping Block ECB Series #

The ECB Series features permanent magnetic clamping blocks, offering a maintenance-free and energy-efficient solution for workpiece holding. These blocks are suitable for a variety of machining tasks, providing consistent holding power without the need for electrical input.

ECB Series Example 1

ECB Series Example 1

ECB Series Example 2

ECB Series Example 2

ECB Series Example 3

ECB Series Example 3

ECB Series Example 4

ECB Series Example 4

ECB Series Example 5

ECB Series Example 5

ECB Series Example 6

ECB Series Example 6

ECB Series Example 7

ECB Series Example 7

ECB Series Example 8

ECB Series Example 8

ECB Series Example 9

ECB Series Example 9

ECB Series Example 10

ECB Series Example 10

ECB Series Example 11

ECB Series Example 11

ECB Series Example 12

ECB Series Example 12

ECB Series Example 13

ECB Series Example 13

ECB Series Example 14

ECB Series Example 14

ECB Series Example 15

ECB Series Example 15

ECB Series Example 16

ECB Series Example 16

ECB Series Example 17

ECB Series Example 17

ECB Series Example 18

ECB Series Example 18

ECB Series Example 19

ECB Series Example 19

ECB Series Example 20

ECB Series Example 20

For further details, product specifications, and additional application cases, please refer to the respective product information links above.