Advancing Precision in Horizontal Lathe and Grinding Machining #

Electro-Permanent Magnetic Chucks, particularly the EEPM-CIR/EEPM-CIRS Series, offer innovative solutions for workholding in horizontal lathe and grinding operations. These magnetic chucks are engineered to provide secure, stable, and efficient clamping for a variety of workpieces, supporting high-precision machining and grinding tasks.

Key Features and Benefits #

- Consistent Clamping Force: Electro-permanent technology ensures a reliable and uniform magnetic hold, minimizing the risk of workpiece movement during machining.

- Enhanced Efficiency: Quick setup and release streamline the workflow, reducing downtime and increasing productivity.

- Versatility: Suitable for a wide range of workpiece shapes and sizes, making them ideal for both standard and complex machining requirements.

- Safety and Energy Savings: Once magnetized, the chuck maintains its holding force without continuous power supply, enhancing operational safety and reducing energy consumption.

Practical Applications #

Electro-Permanent Magnetic Chucks are widely used in horizontal lathe and grinding machining for:

- Turning, milling, and grinding round or irregularly shaped workpieces

- Applications requiring high accuracy and repeatability

- Situations where traditional mechanical clamping is challenging or time-consuming

Visual Gallery: Real-World Use Cases #

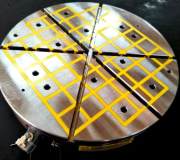

Horizontal Lathe Machining Example 1

Horizontal Lathe Machining Example 1

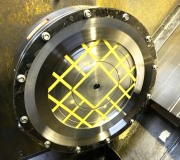

Horizontal Lathe Machining Example 2

Horizontal Lathe Machining Example 2

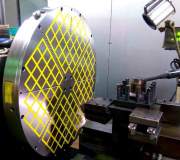

Horizontal Lathe Machining Example 3

Horizontal Lathe Machining Example 3

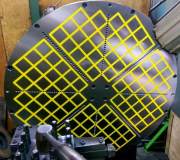

Horizontal Lathe Machining Example 4

Horizontal Lathe Machining Example 4

Horizontal Lathe Machining Example 5

Horizontal Lathe Machining Example 5

Horizontal Lathe Machining Example 6

Horizontal Lathe Machining Example 6

Horizontal Lathe Machining Example 7

Horizontal Lathe Machining Example 7

Horizontal Lathe Machining Example 8

Horizontal Lathe Machining Example 8

Horizontal Lathe Machining Example 9

Horizontal Lathe Machining Example 9

Horizontal Lathe Machining Example 10

Horizontal Lathe Machining Example 10

Horizontal Lathe Machining Example 11

Horizontal Lathe Machining Example 11

Horizontal Lathe Machining Example 12

Horizontal Lathe Machining Example 12

Horizontal Lathe Machining Example 13

Horizontal Lathe Machining Example 13

Horizontal Lathe Machining Example 14

Horizontal Lathe Machining Example 14

Horizontal Lathe Machining Example 15

Horizontal Lathe Machining Example 15

Product Information #

For more details about the EEPM-CIR/EEPM-CIRS Series Electro-Permanent Magnetic Chucks, visit the product information page.