Advanced Workholding for Linear Guideway and Slide Block Machining #

Electro-permanent magnetic chucks, particularly the EEPML Series, offer a reliable and efficient solution for machining linear guideways and slide blocks. These chucks are designed to securely hold high-precision or high-accuracy oblong workpieces during drilling, grinding, and other machining processes. Their robust clamping force ensures stability, which is essential for maintaining tight tolerances and achieving superior surface finishes.

Key Features #

- Suitable for high-precision and high-accuracy machining of oblong workpieces

- Ideal for drilling, grinding, and other demanding operations

- Enhances workholding stability and machining efficiency

Learn more about the EEPML Series and its applications.

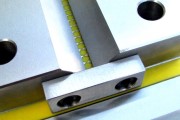

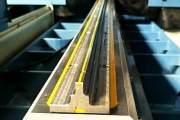

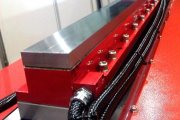

Practical Case Gallery #

Below are real-world examples showcasing the use of electro-permanent magnetic chucks in linear guideway and slide block machining. These images illustrate various setups and workpiece configurations, providing insight into the versatility and effectiveness of these workholding solutions.

Practical Case 1

Practical Case 1

Practical Case 2

Practical Case 2

Practical Case 3

Practical Case 3

Practical Case 4

Practical Case 4

Practical Case 5

Practical Case 5

Practical Case 6

Practical Case 6

Practical Case 7

Practical Case 7

Practical Case 8

Practical Case 8

Practical Case 9

Practical Case 9

Practical Case 10

Practical Case 10

Practical Case 11

Practical Case 11

Practical Case 12

Practical Case 12

Practical Case 13

Practical Case 13

Practical Case 14

Practical Case 14

Practical Case 15

Practical Case 15

Practical Case 16

Practical Case 16

Practical Case 17

Practical Case 17

Practical Case 18

Practical Case 18

Practical Case 19

Practical Case 19

Practical Case 20

Practical Case 20

Practical Case 21

Practical Case 21

Practical Case 22

Practical Case 22

Practical Case 23

Practical Case 23

Practical Case 24

Practical Case 24

For more information and additional resources, visit the product information page.