Innovative Magnetic Clamping for Efficient Mold Changes in Injection Molding #

The plastic injection molding industry demands precision, speed, and safety in mold changing operations. The Electro-Permanent Magnetic Chuck EEPM-PIM Series offers a modern solution, streamlining the mold change process and enhancing productivity across a wide range of injection molding machines.

Overview of EEPM-PIM Series #

The EEPM-PIM Series is designed specifically for plastic injection molding applications, providing robust and reliable magnetic clamping for quick mold changes. This technology ensures secure holding force, reduces downtime, and supports both horizontal and vertical machine configurations.

Practical Applications and Case Studies #

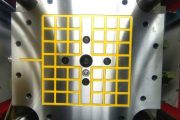

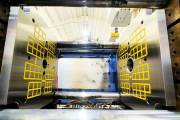

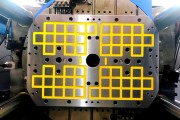

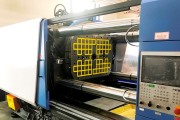

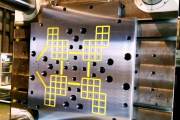

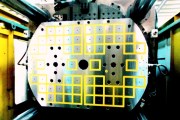

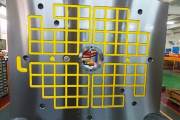

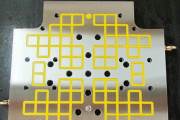

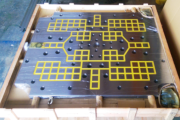

A comprehensive gallery of real-world installations demonstrates the versatility and effectiveness of the EEPM-PIM Series. These cases cover a variety of machine sizes and operational scenarios, from compact 120T units to large-scale 1800T systems, as well as vertical and automated applications.

Image Gallery: Real-World Installations #

Practical Case 1

Practical Case 1

Practical Case 2

Practical Case 2

Practical Case 3

Practical Case 3

Practical Case 4

Practical Case 4

Practical Case 5

Practical Case 5

Practical Case 6

Practical Case 6

Practical Case 7

Practical Case 7

Practical Case 8

Practical Case 8

Practical Case 9

Practical Case 9

Practical Case 10

Practical Case 10

Practical Case 11

Practical Case 11

Practical Case 12

Practical Case 12

Practical Case 13

Practical Case 13

Practical Case 14

Practical Case 14

Practical Case 15

Practical Case 15

Practical Case 16

Practical Case 16

Practical Case 17

Practical Case 17

Practical Case 18

Practical Case 18

Practical Case 19

Practical Case 19

Practical Case 20

Practical Case 20

Practical Case 21

Practical Case 21

Practical Case 22

Practical Case 22

Practical Case 23

Practical Case 23

Practical Case 24

Practical Case 24

Practical Case 25

Practical Case 25

Practical Case 26

Practical Case 26

Practical Case 27

Practical Case 27

Practical Case 28

Practical Case 28

Practical Case 29

Practical Case 29

Practical Case 30

Practical Case 30

Practical Case 31

Practical Case 31

Practical Case 32

Practical Case 32

Practical Case 33

Practical Case 33

Practical Case 34

Practical Case 34

Practical Case 35

Practical Case 35

Practical Case 36

Practical Case 36

Practical Case 37

Practical Case 37

Practical Case 38

Practical Case 38

Practical Case 39

Practical Case 39

Practical Case 40

Practical Case 40

Practical Case 41

Practical Case 41

Practical Case 42

Practical Case 42

Practical Case 43

Practical Case 43

Practical Case 44

Practical Case 44

Practical Case 45

Practical Case 45

Practical Case 46

Practical Case 46

Practical Case 47

Practical Case 47

Practical Case 48

Practical Case 48

Practical Case 49

Practical Case 49

Practical Case 50

Practical Case 50

Practical Case 51

Practical Case 51

Practical Case 52

Practical Case 52

Practical Case 53

Practical Case 53

Practical Case 54

Practical Case 54

Practical Case 55

Practical Case 55

Practical Case 56

Practical Case 56

Practical Case 57

Practical Case 57

Practical Case 58

Practical Case 58

Practical Case 59

Practical Case 59

Practical Case 60

Practical Case 60

Practical Case 61

Practical Case 61

Practical Case 62

Practical Case 62

Practical Case 63

Practical Case 63

Practical Case 64

Practical Case 64

Practical Case 65

Practical Case 65

Practical Case 66

Practical Case 66

Practical Case 67

Practical Case 67

Solutions for Various Machine Sizes and Applications #

The EEPM-PIM Series supports a wide range of injection molding machine tonnages, including:

- 120T

- 180T

- 250T

- 550T

- 750T

- 950T

- 1200T

- 1600T

- 1800T

Additionally, the system is adaptable for vertical applications and can be integrated into automated production lines, further enhancing operational flexibility.

For more details on each application, visit the respective sections:

Learn More #

For further information, technical details, or to explore more practical cases and videos, please visit the Products Information page.