Advanced Magnetic Workholding for Rack Machining #

Electro-Permanent Magnetic Chuck EEPM Series offers a reliable and efficient solution for rack machining applications. Designed to provide strong and stable clamping, these magnetic chucks are ideal for securing workpieces during various machining processes, ensuring high precision and operational safety.

Product Overview #

The EEPM Series Electro-Permanent Magnetic Chucks are engineered for demanding rack machining tasks. Their robust magnetic force ensures that racks and similar workpieces are held securely in place, minimizing vibration and movement during milling, drilling, or grinding operations. This results in improved machining accuracy and surface finish.

For more detailed product information, visit the EEPM Magnetic Workholding page.

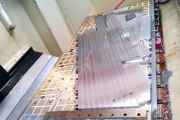

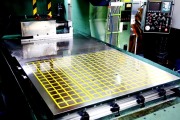

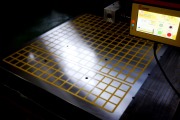

Practical Case Gallery #

Below are real-world examples showcasing the use of EEPM Series chucks in rack machining environments. These images illustrate the versatility and effectiveness of magnetic workholding solutions in various setups.

Rack Machining Case 1

Rack Machining Case 1

Rack Machining Case 2

Rack Machining Case 2

Rack Machining Case 3

Rack Machining Case 3

Rack Machining Case 4

Rack Machining Case 4

Rack Machining Case 5

Rack Machining Case 5

Rack Machining Case 6

Rack Machining Case 6

Rack Machining Case 7

Rack Machining Case 7

Rack Machining Case 8

Rack Machining Case 8

Rack Machining Case 9

Rack Machining Case 9

Rack Machining Case 10

Rack Machining Case 10

Rack Machining Case 11

Rack Machining Case 11

Rack Machining Case 12

Rack Machining Case 12

Rack Machining Case 13

Rack Machining Case 13

Rack Machining Case 14

Rack Machining Case 14

Rack Machining Case 15

Rack Machining Case 15

Learn More #

For further details on magnetic workholding solutions and their applications in rack machining, please refer to the product information page.