Advanced Magnetic Workholding for Rail Machining #

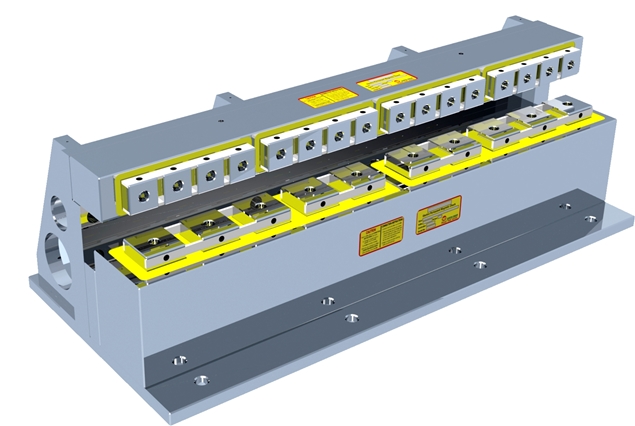

Railway component manufacturing demands high precision, stability, and efficiency. Electro-permanent magnetic chucks, such as the EEPM Series, offer a reliable solution for securely clamping rail workpieces during machining processes. These chucks are engineered to meet the rigorous requirements of rail machining, ensuring both safety and accuracy in production environments.

Key Features and Benefits #

- Secure Clamping: Electro-permanent magnetic chucks provide strong, uniform holding force across the entire workpiece, minimizing vibration and movement during machining.

- Enhanced Precision: The stable clamping surface supports high-accuracy operations, essential for the tight tolerances required in rail manufacturing.

- Operational Efficiency: Quick setup and release reduce downtime, streamlining the workflow for both small-batch and mass production.

- Versatility: Suitable for a variety of rail profiles and sizes, these chucks adapt to different machining tasks, including drilling, milling, and grinding.

- Safety: The fail-safe design ensures that the workpiece remains securely held even in the event of a power loss, protecting both operators and equipment.

Application Scenarios #

Electro-permanent magnetic chucks are widely used in:

- Machining of railway rails and related components

- Surface grinding and finishing of long, heavy workpieces

- Drilling and milling operations requiring stable, vibration-free clamping

For more detailed product information, visit the EEPM Series Electro-Permanent Magnetic Chucks page.

Gallery: Rail Machining in Action #

Additional Application Images #

Rail Machining Example 1

Rail Machining Example 1

Rail Machining Example 2

Rail Machining Example 2

Rail Machining Example 3

Rail Machining Example 3

Rail Machining Example 4

Rail Machining Example 4

Rail Machining Example 5

Rail Machining Example 5

Rail Machining Example 6

Rail Machining Example 6

Rail Machining Example 7

Rail Machining Example 7

For further inquiries or to discuss custom solutions for your rail machining needs, please contact us.