Magnetic Workholding Solutions for Automated Manufacturing #

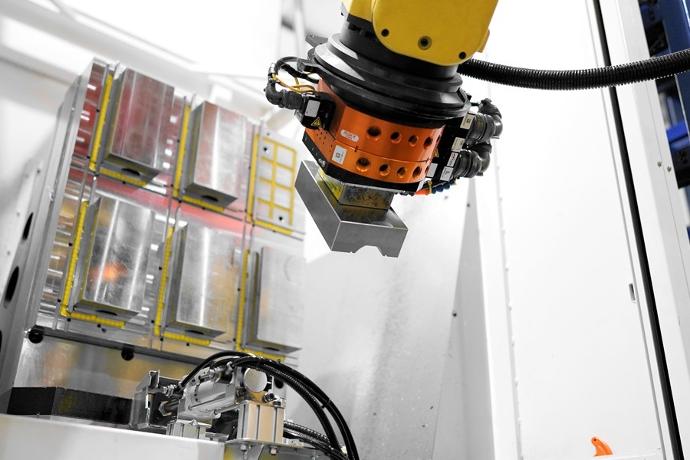

Permanent magnet electric chucks are transforming automated production by providing precise and stable workpiece holding. These solutions are particularly well-suited for CNC machines and robotic systems, driving improvements in efficiency, safety, and workflow flexibility across modern manufacturing lines.

Key Advantages of Permanent Magnet Electric Chucks #

- Energy Efficiency: These chucks consume power only during magnetization and demagnetization, significantly reducing energy usage during operation. This makes them ideal for sustainable manufacturing environments.

- High Holding Force: With robust and stable magnetic force, they ensure precise and secure clamping of workpieces, which is essential for high-precision machining in automated production lines.

- Safety and Reliability: The magnetic force remains stable even during power outages, preventing accidents or displacement of workpieces and enhancing operational safety.

- Easy Integration: Their compact design and straightforward control interfaces allow seamless integration with CNC machines and robotic arms, optimizing production workflows and increasing flexibility.

Product Series for Automated Production #

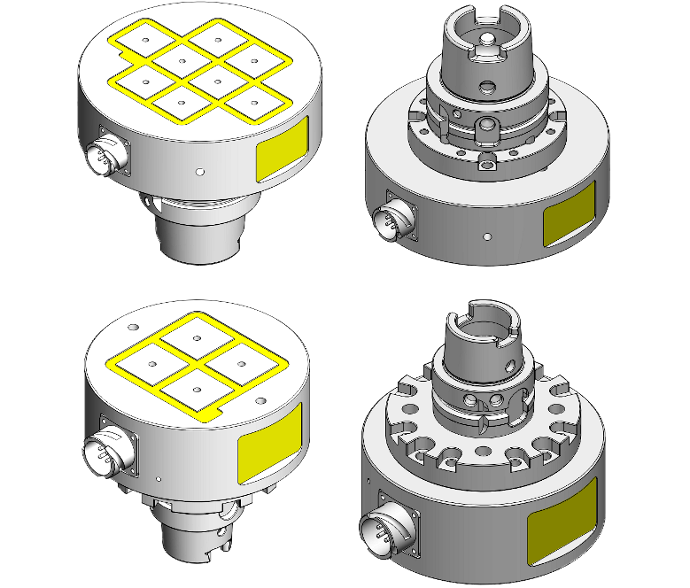

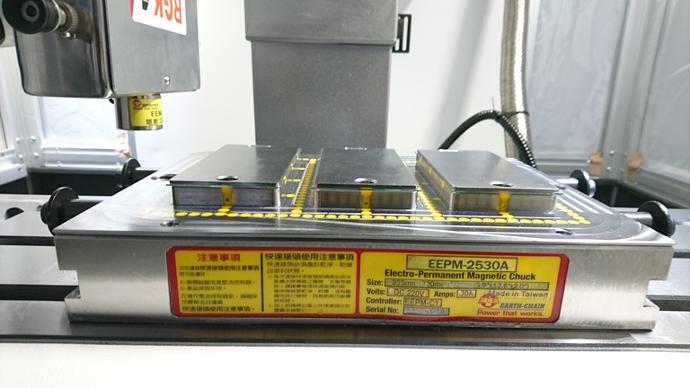

EEPM-V Series #

- Multi-zone Cooperative Control Magnetic Chuck System

- Designed for automatic processing with multi-workpiece clamping.

- Discover more

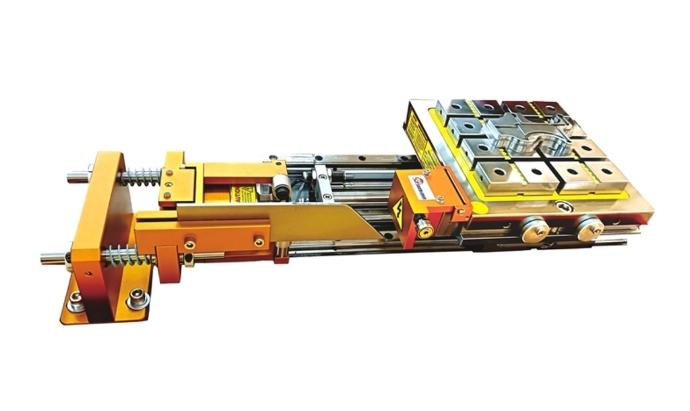

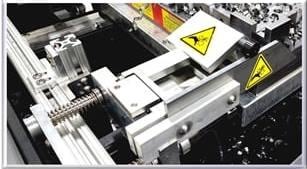

EEPM-SAC Series #

- Automated Self-Aligning Connection Magnetic System

- Enables automatic cable connection for magnetization and demagnetization operations.

- Discover more

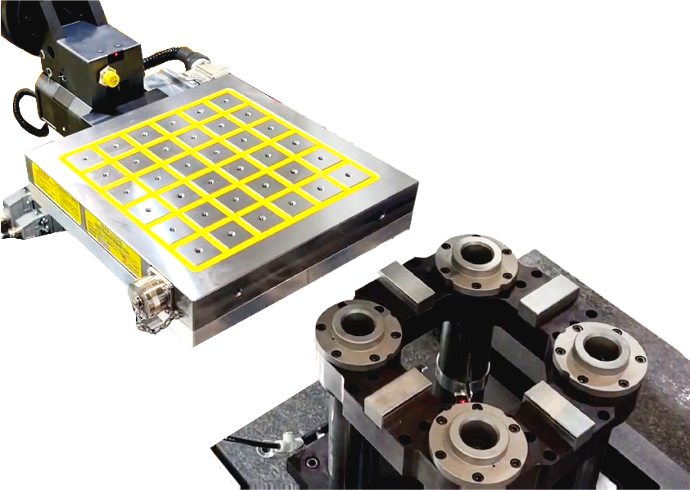

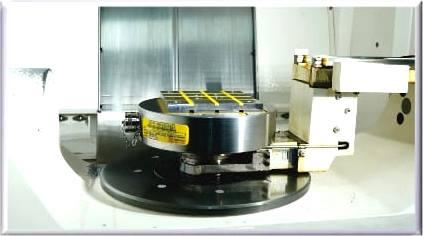

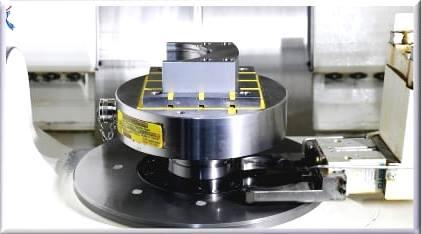

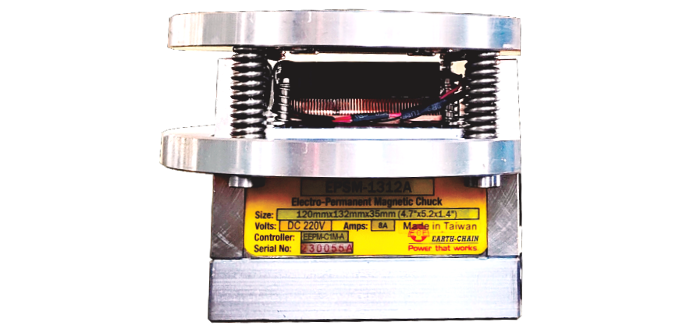

EEPM Series #

- Automatic Zero Point Positioning Magnetic Chuck Changing System

- Facilitates precise, automatic exchange of multiple magnetic chucks.

- Discover more

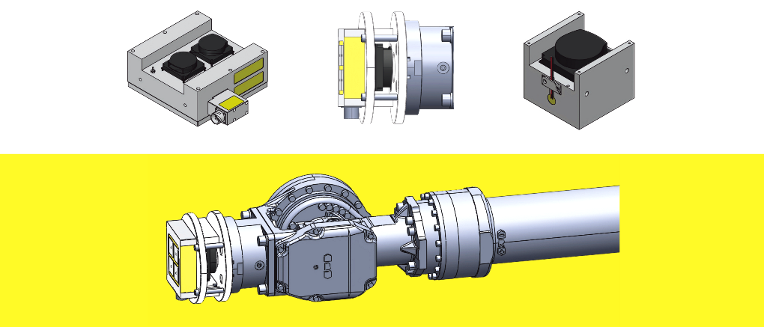

EEPM-CIRTA Series #

- Tool Arbor Type Quick Changing Magnetic Chuck System

- Enables automatic, precise exchange of multiple round magnetic chucks.

- Discover more

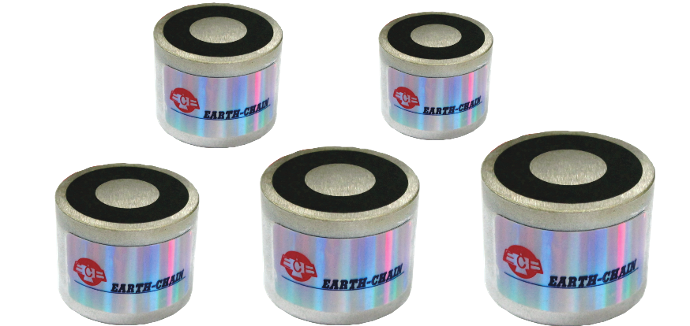

PECM Series #

- Permanent Electro-Magnet

- Suitable for use with automatic robotic arm clamping.

- Discover more

ECM Series #

- Electro-Magnet

- Designed for automatic robotic arm clamping.

- Discover more

EPSM Series #

- Electro-Permanent Magnetic Chuck

- Suitable for use with automatic robotic arm clamping.

- Discover more

EPSM-SC Series #

- Magnetic System with Silicon Cooling Chip

- Designed for magnetic chuck systems requiring rapid and repeated magnetization and demagnetization.

- Discover more

ECB Series #

- Permanent Magnetic Clamping Block

- Enables automation in production lines with ECB Series blocks.

- Discover more