Advancing Horizontal Machining with Magnetic Clamping #

Magnetic clamping technology is transforming horizontal machining by delivering robust, uniform workpiece holding without obstructing access. This approach enables efficient multi-face machining, significantly reduces setup time, minimizes part deformation, and enhances stability during side-load cutting operations.

Key Benefits of Magnetic Clamping in Horizontal Machining #

- Strong, Uniform Holding: Ensures the workpiece remains securely in place, even during demanding operations.

- Unobstructed Access: Facilitates multi-face machining by eliminating traditional clamps that can block tool paths.

- Reduced Setup Time: Streamlines the process, allowing for faster changeovers and increased productivity.

- Minimized Deformation: Distributes clamping force evenly, reducing the risk of part distortion.

- Enhanced Stability: Provides reliable support during side-load and heavy-duty cutting.

Featured Magnetic Clamping Solutions #

EEPM-V Series: Electro-Permanent Magnetic Chuck #

Specially designed for use with CNC horizontal machining centers, the EEPM-V Series offers powerful and reliable magnetic workholding for a variety of machining tasks.

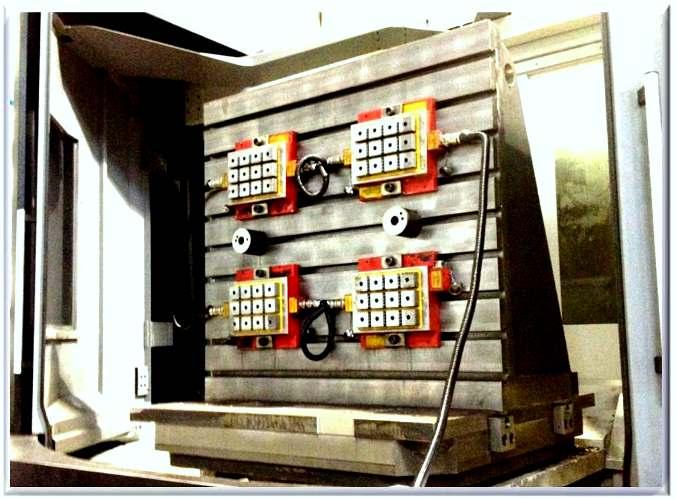

EEPM-V Series Electro-Permanent Magnetic Chuck

EEPM-V Series Electro-Permanent Magnetic Chuck

EEPM-C Series: Electro-Permanent Magnetic Chuck #

The EEPM-C Series is suitable for large vertical lathes, double column machining centers, and CNC machining centers, offering versatility for various large-scale applications.

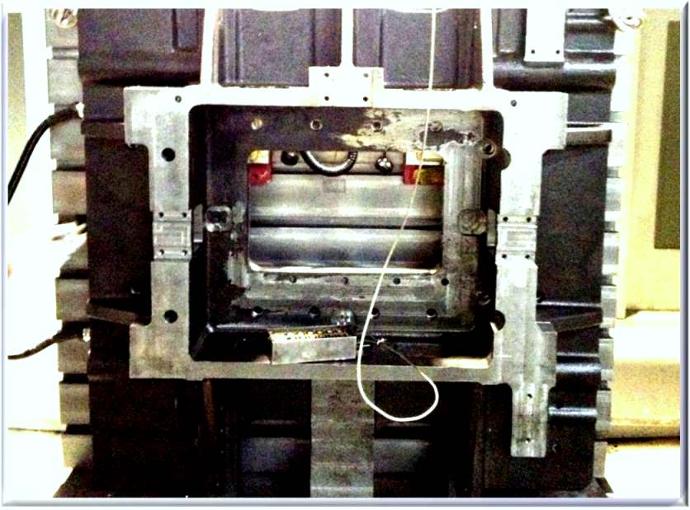

EEPM-C Series Electro-Permanent Magnetic Chuck

EEPM-C Series Electro-Permanent Magnetic Chuck

ECB-120V12: Permanent Magnetic Clamping Block #

Designed for CNC horizontal machining centers, the ECB-120V12 provides a permanent magnetic solution for secure and flexible workholding.

Ready to Optimize Your Machining Projects? #

Discover how magnetic technologies can streamline your operations and improve machining outcomes. Get In Touch Today!

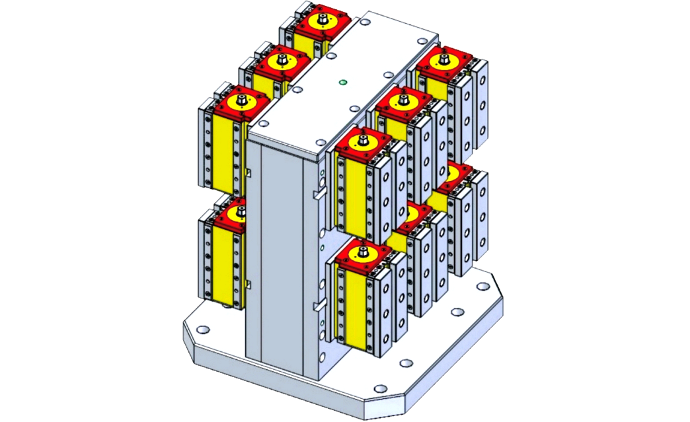

ECB-120V12 Permanent Magnetic Clamping Block

ECB-120V12 Permanent Magnetic Clamping Block