Enhancing Multi-Pallet Machining with Magnetic Workholding Solutions #

Magnetic fixtures have become a pivotal component in modern multi-pallet machining environments. Their unique properties deliver several operational advantages that help manufacturers achieve greater efficiency, flexibility, and precision.

Key Advantages of Magnetic Fixtures in Multi-Pallet Machining #

- Rapid Part Changeovers: Magnetic workholding enables quick and seamless transitions between different workpieces, minimizing downtime and maximizing productivity across multiple pallets.

- Consistent Clamping Without Deformation: Unlike traditional mechanical clamps, magnetic fixtures provide uniform holding force without causing mechanical deformation to the workpiece, ensuring high-quality results.

- Versatile Support for Various Workpiece Shapes: The adaptability of magnetic fixtures allows for secure clamping of a wide range of workpiece geometries, making them suitable for diverse machining tasks.

- Simplified Automation: Magnetic workholding systems integrate smoothly with automated processes, reducing manual intervention and supporting efficient, unattended operations.

- Improved Tool Access and Reduced Cycle Times: By eliminating the need for complex mechanical clamps, magnetic fixtures offer better tool accessibility, which in turn shortens machining cycles and enhances overall throughput.

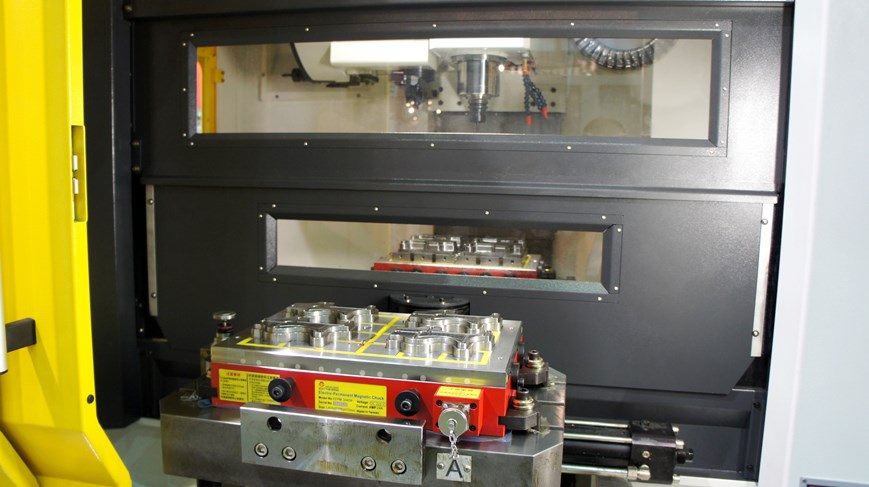

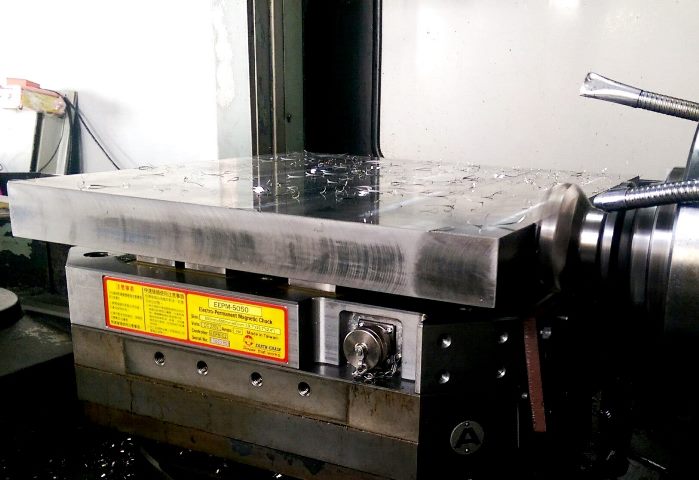

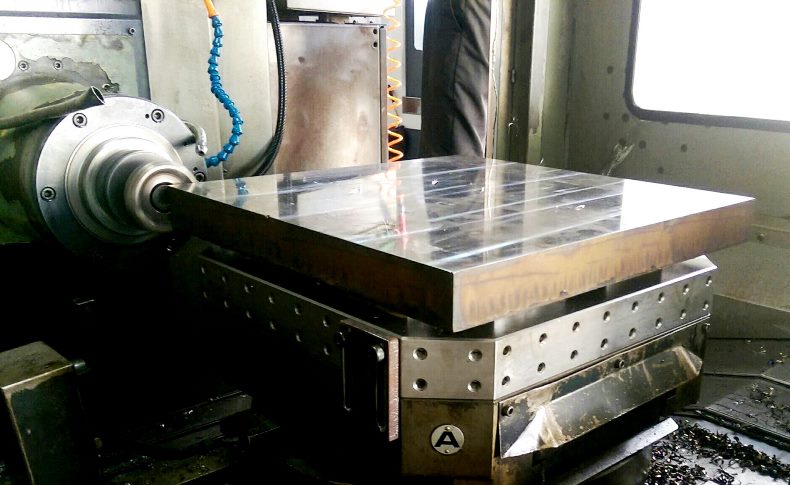

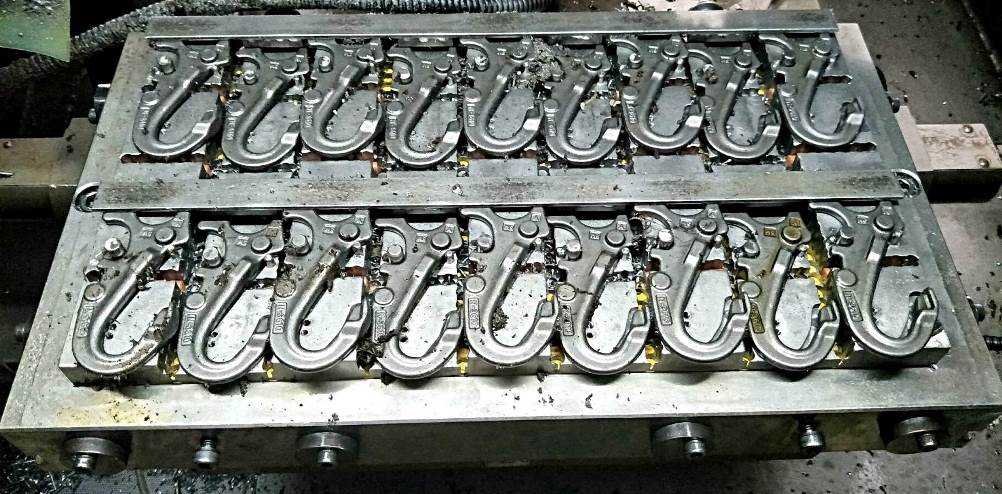

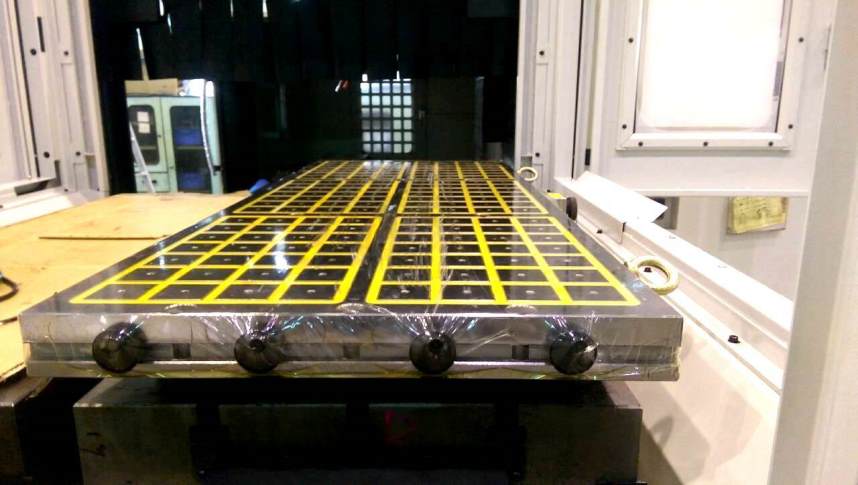

Practical Applications: Visual Insights #

Ready to Optimize Your Projects with Magnetic Technologies? #

Explore More:

- Selected Products

- Automatic Clamping System

- Magnetic Workholding

- Customized Magnetic Chuck

- Electro Permanent Magnetic Chuck

- Optional Accessories - EEPM Series

- Magnetic Clamping Block

- Magnetic Surface Grinder

- Quick Mold Change Systems

- Linear Grinding

- Battery Powered Lifting Magnets

- Permanent Lifting Magnet

- Drill Grinder / End Mill Re-Sharpener

- Universal Magnetic Stand

- Magnetic Tools

- Magnetic Polishing Machine

Related Applications:

- Automated Production Applications

- Precision Grinding Applications

- Vertical Machining Applications

- Horizontal Machining Applications

- Double Column Machining Applications

- Customization Applications

- Round Workpieces Machining Applications

- 4 Axis Machining Applications

- Linear Guideway & Sliding Block Machining Applications

- Quick Mold Changing Applications

- Rail Machining Applications

- Multi-Pallet Machining Applications