Innovative Magnetic Workholding for Precision Grinding #

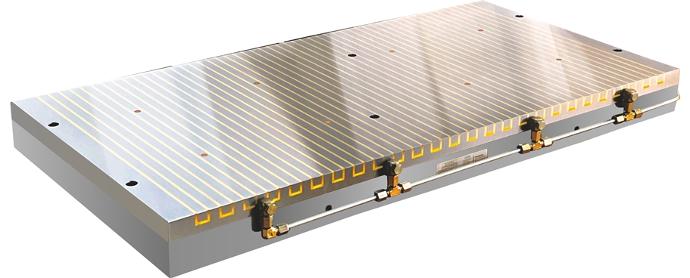

Electro-permanent magnetic chucks are engineered to deliver reliable, high-precision workholding for surface grinding and related applications. These systems combine robust magnetic force with energy efficiency and operational safety, making them ideal for demanding manufacturing environments.

Key Features of Electro-Permanent Magnetic Chucks #

- No Continuous Power Required: Once magnetized, the chuck maintains its holding force without ongoing electrical supply, eliminating heat generation that could affect workpiece accuracy.

- Energy Efficiency: Power is only used during magnetization and demagnetization, significantly reducing energy consumption.

- Stable and Eco-Friendly Construction: The resin-bonded face plate minimizes environmental impact while ensuring structural integrity.

- Residual Magnetism Prevention: The reverse demagnetization design, along with an optional air blow system, facilitates easy workpiece removal and prevents unwanted residual magnetism.

- Durable and Waterproof: Multi-layer waterproofing and a dense structural design provide excellent chuck strength and resistance to coolant ingress.

- Versatile Pole Pitch Options: Multiple magnetic pole pitches are available, accommodating a wide range of workpiece sizes and shapes. Chucks can be combined for use on large or gantry-type surface grinders.

- Customizable Solutions: Standard and custom sizes are offered to meet specific user requirements, optimizing cost performance.

Controller Capabilities #

- LCD Display: Real-time controller and chuck status are clearly shown for user convenience.

- Remote Operation: Compatible with a cable control box for flexible operation.

- Certified Safety: Equipped with a UL-certified European standard power terminal block, supporting up to 500V/32A for safe and reliable use.

- Integrated Control: Magnetization, demagnetization, and magnetic force adjustment can be managed directly from the machine’s main operation panel.

- Adjustable Magnetic Force: Up to 16-segment magnetic force adjustment (8-segment via cable control box) allows precise tuning for different grinding operations and workpiece conditions.

Technical Specifications #

Electro-permanent magnetic chucks are available in a variety of models, dimensions, and pole pitches to suit diverse grinding needs. Multiple chucks can be combined and controlled simultaneously, with custom sizes and pole pitches available upon request.

Rectangular Chuck Models (Selected Examples) #

| Model | Dimensions (mm) | Pole Pitch (mm) | Controller | Voltage | Weight (kg) |

|---|---|---|---|---|---|

| EEPG-2040A | 400 x 200 x 65 | 1+3 | EEPG-C1 | 220V or 380V~440V | 41 |

| EEPG-3050A | 500 x 300 x 65 | 1+3 | EEPG-C1 | 220V or 380V~440V | 77 |

| EEPG-3060A | 600 x 300 x 65 | 1+3 | EEPG-C1 | 220V or 380V~440V | 92 |

| EEPG-4080A | 800 x 400 x 65 | 1+3 | EEPG-C1 | 220V or 380V~440V | 164 |

Additional models are available with pole pitches of 3+10mm, 3+15mm, and 5+20mm, as well as larger sizes for gantry and large-scale grinders.

Circular Chuck Models (Selected Examples) #

| Model | Diameter (mm) | Height (mm) | Magnetic Area (mm) | Pole Pitch (mm) | Controller | Voltage | Weight (kg) |

|---|---|---|---|---|---|---|---|

| EEPG-500BR | 500 | 85 | 374 | 3+10 | EEPG-C1 | 380V~400V | 132 |

| EEPG-600BR | 600 | 85 | 420 | 3+10 | EEPG-C1 | 380V~400V | 190 |

| EEPG-800BR | 800 | 90 | 634 | 3+10 | EEPG-C2 | 380V~400V | 358 |

| EEPG-1000BR | 1000 | 100 | 790 | 3+10 | EEPG-C2 | 380V~400V | 621 |

Other pole pitch and size combinations are available to suit specific application requirements.

Practical Applications #

Electro-permanent magnetic chucks are widely used in precision surface grinding, especially where high accuracy and repeatability are essential. Their robust design and flexible control options make them suitable for both standard and custom grinding setups, including large-scale and gantry-type machines.

For further details or to discuss custom requirements, please contact us.