Magnetic Quick Mold Change Systems: Enhancing Efficiency and Safety #

Magnetic quick mold change systems are transforming the way manufacturers handle mold switching in plastic injection processes. By leveraging advanced magnetic technology, these systems enable rapid mold changes, significantly reducing downtime and boosting overall production efficiency. The elimination of bolts and manual clamping not only streamlines operations but also enhances workplace safety. Additionally, these systems help lower labor costs and support flexible manufacturing, making it easier to adapt to varying production requirements.

EEPM-PIM Series Overview #

The EEPM-PIM Series is designed specifically for quick mold change applications in plastic injection machines. This system offers a range of features that address the needs of modern manufacturing environments:

Key Features #

- Electro-Permanent Magnetic System: Enables power ON and OFF control within 2 to 10 seconds. Once activated, no continuous power supply is required to maintain the magnetic hold, ensuring safety even during power failures.

- Temperature Stability: The system does not heat up or deform molds, maintaining product integrity.

- Customizable Magnetic Force: Available in three pole sizes to match different mold requirements.

- Dual Pole Design: The magnetic chuck features both N/S poles, preventing magnetization of the machine frame and related equipment parts.

- Consistent Clamping Force: Even distribution of clamping force across the mold surface reduces product burrs and extends mold life.

- Time and Efficiency Gains: Mold setting time can be reduced by up to 70%, leading to shorter delivery times and increased productivity.

- Enhanced Machine Structure: Improves the strength and parallelism of the machine’s movable and stationary plates, as well as the frame.

- Expanded Clamping Area: Increases the clamping area by 20%, accommodates all mold shapes, and reduces maintenance needs.

- High Temperature Compatibility: Operates safely at temperatures up to 120℃, suitable for demanding production environments.

- Clean Working Environment: No oil is required, supporting stable quality and compliance with high-specification, germ-free, or dust-free requirements.

Technical Specifications #

The EEPM-PIM Series is engineered for various mold thicknesses and sizes, with three distinct pole sizes to ensure optimal clamping safety. Each pole size offers a different magnetic field height and force:

| Model No. | Pole Size (mm) | Chuck Height (mm) | Magnetic Field Height (mm) | Magnetic Force (kgf/4 poles) |

|---|---|---|---|---|

| EPM-PIM-B Series | 50 x 50 | 35~60 | 25 | 1250 ±5% |

| EPM-PIM-D Series | 70 x 70 | 70 | 40 | 2800 ±5% |

| EPM-PIM-E Series | 92 x 92 | 80 | 50 | 4800 ±5% |

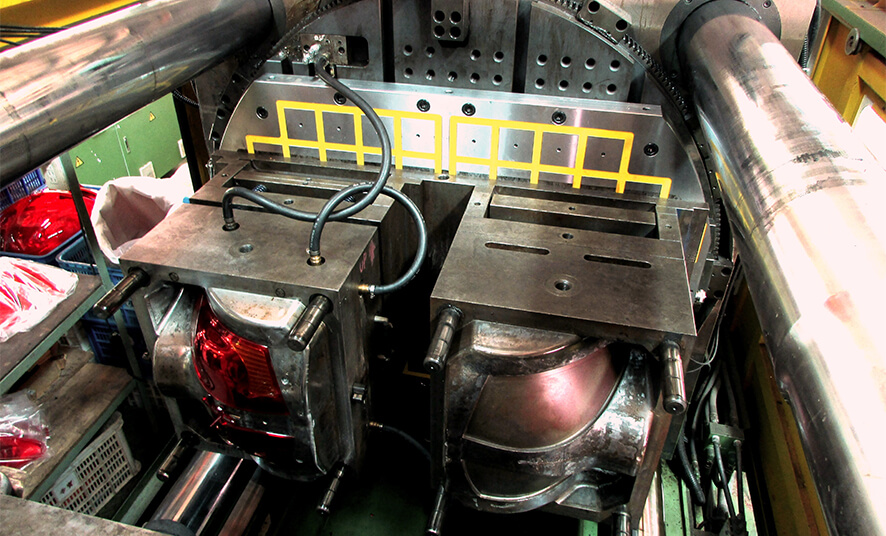

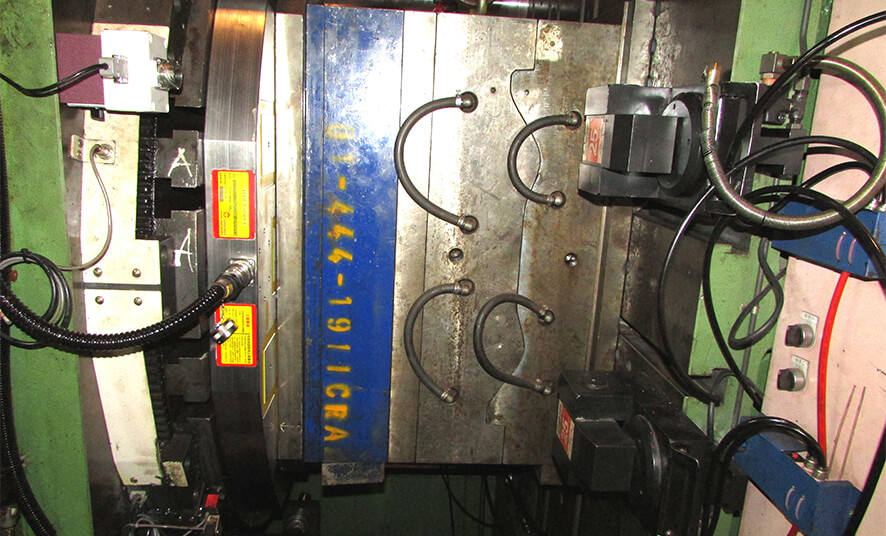

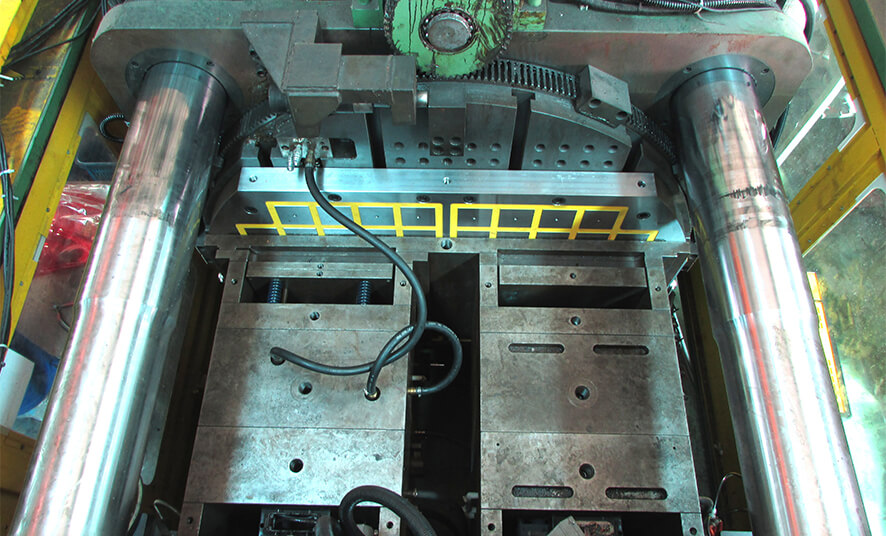

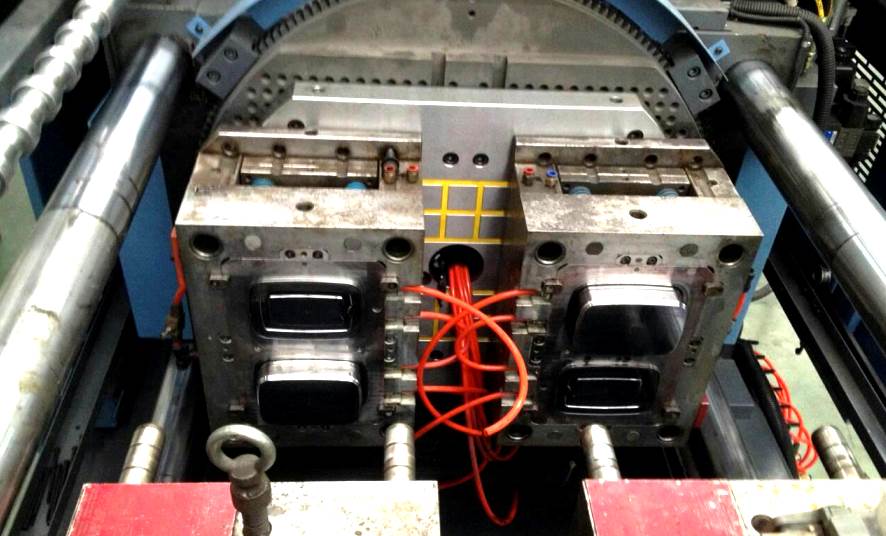

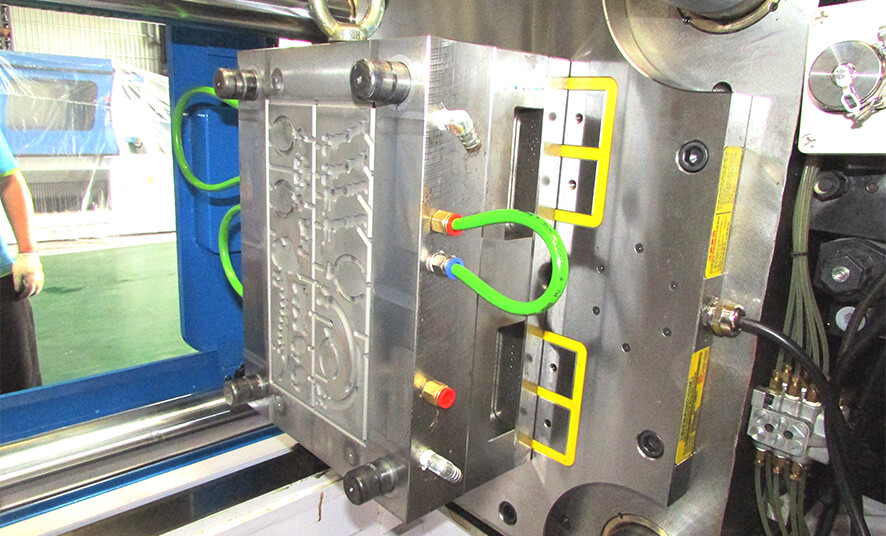

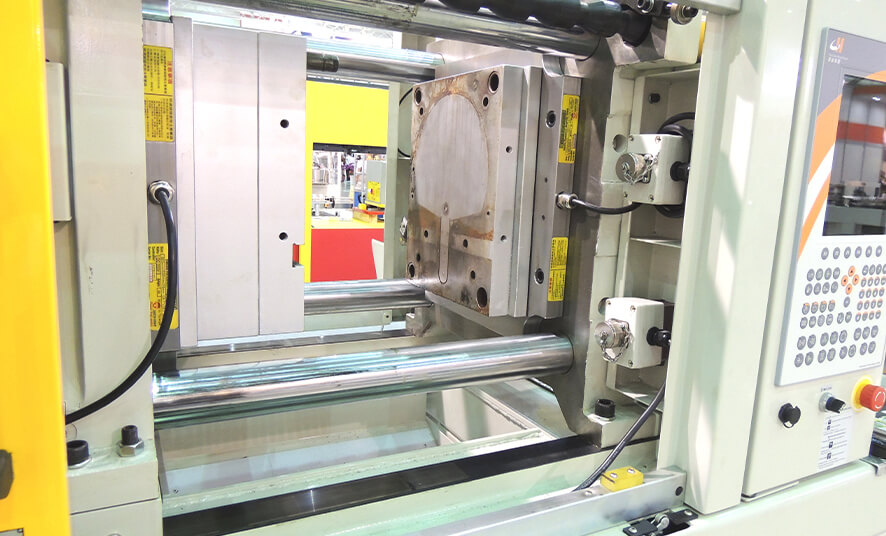

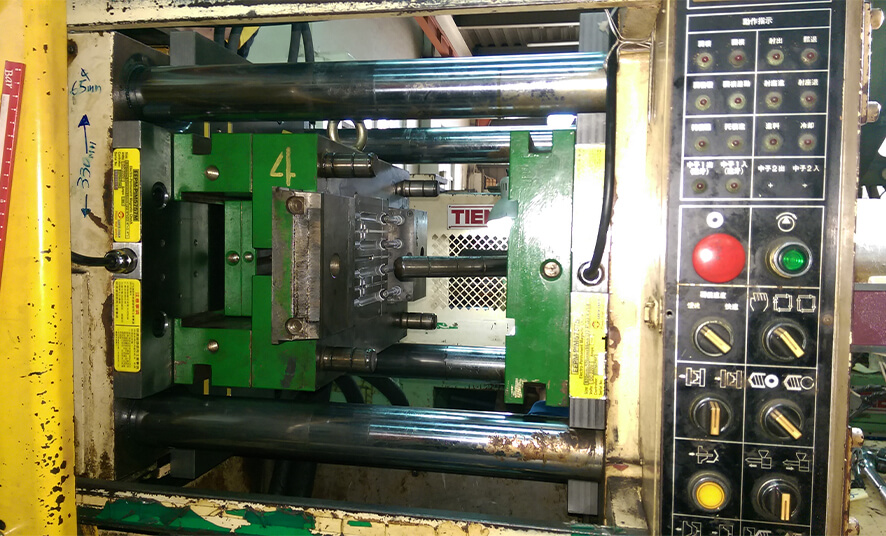

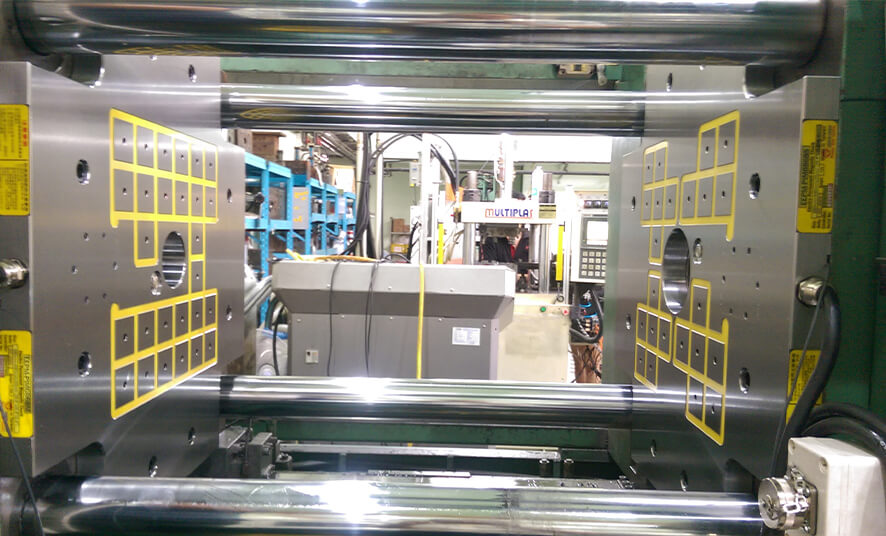

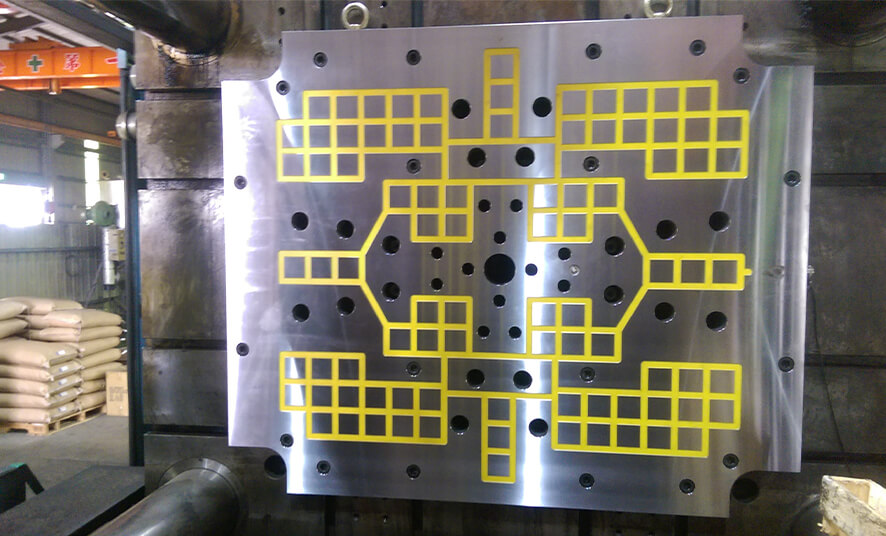

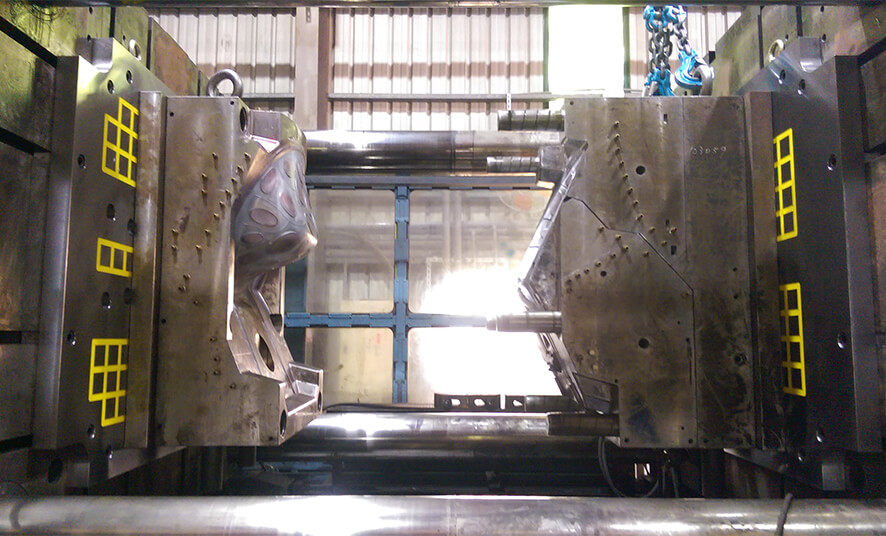

Real-World Applications #

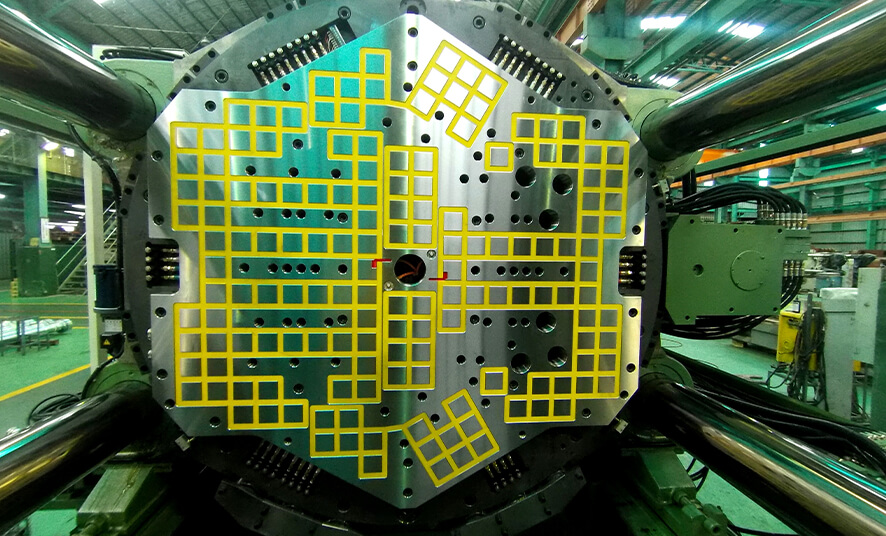

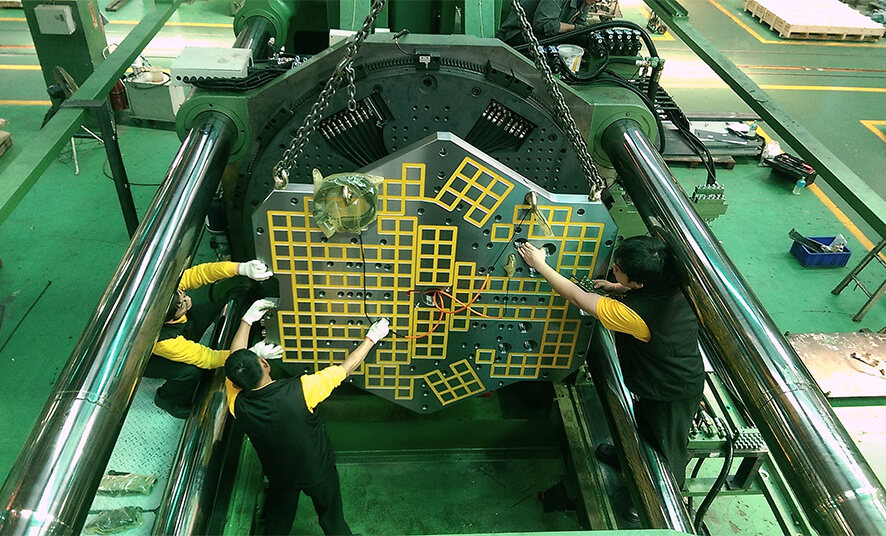

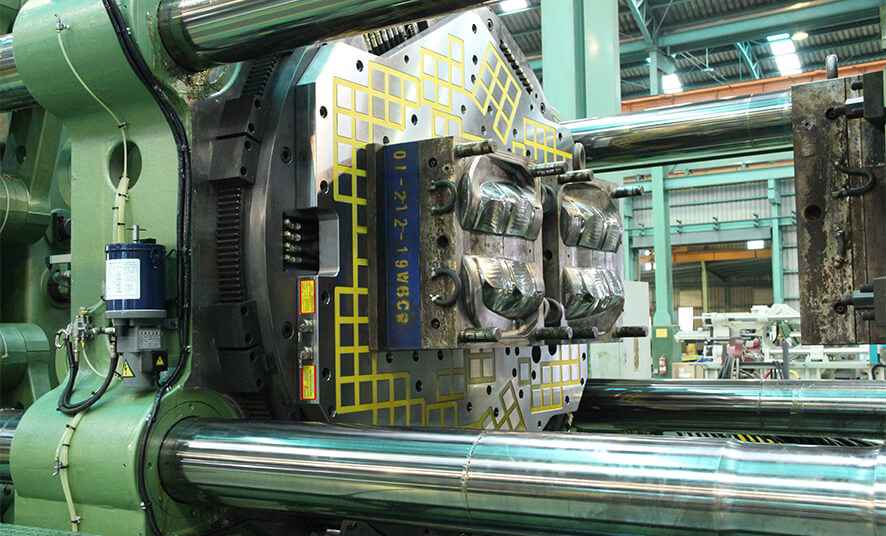

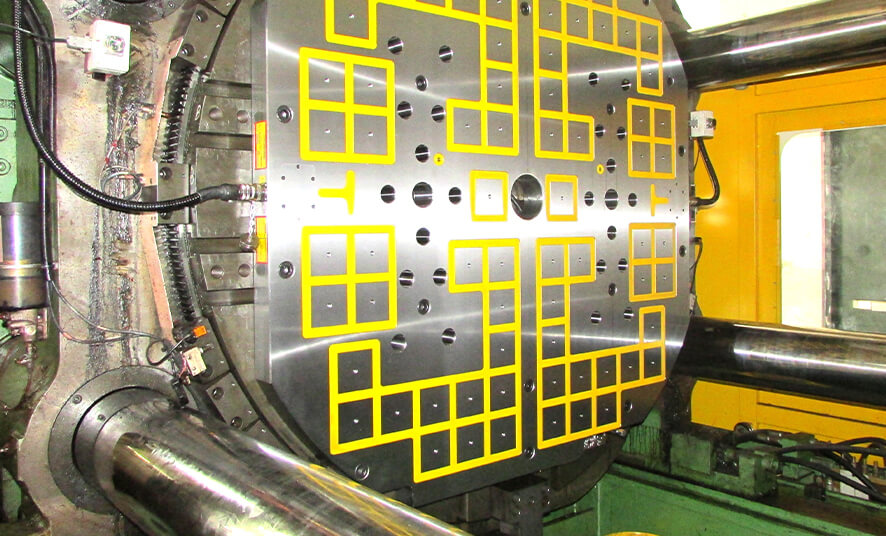

The following gallery showcases practical applications of the EEPM-PIM Series in various production settings:

Application Videos #

For more information or to discuss how magnetic technologies can optimize your production, get in touch today.