Magnetic Clamping Solutions for Enhanced Vertical Machining #

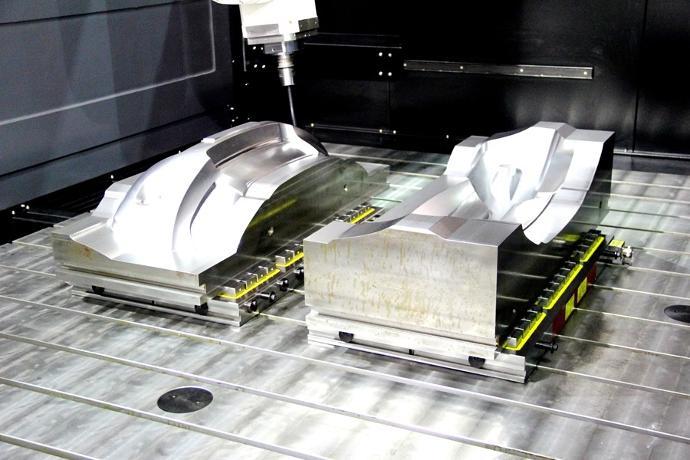

Magnetic clamping technology is transforming vertical machining by offering fast setup, uniform holding force, and five-sided access to workpieces. This approach not only reduces vibration and improves surface finish but also enhances safety by maintaining clamping even during power loss. Ideal for ferromagnetic materials, magnetic clamping boosts both efficiency and precision in machining operations.

Key Advantages of Magnetic Clamping in Vertical Machining #

-

Fast Setup Time

Magnetic clamping enables quick loading and unloading of workpieces, significantly reducing downtime and increasing machining efficiency. This is especially beneficial in high-mix or short-run production environments. -

Uniform Clamping Force

The technology provides consistent holding across the entire surface of the workpiece, minimizing deformation and improving machining accuracy compared to traditional point-based mechanical clamping systems. -

Five-Sided Machining Capability

By holding the workpiece from below, magnetic chucks allow tools to access five faces in a single setup, reducing the need for repositioning and enhancing productivity. -

Vibration Dampening

Magnetic chucks absorb machining vibrations, resulting in better surface finishes, reduced tool wear, and more stable cutting performance during vertical milling operations.

Product Range for Vertical Machining Applications #

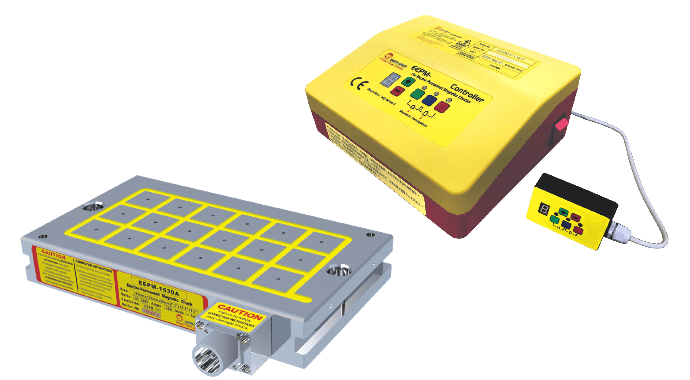

EEPM-A Series: Electro-Permanent Magnetic Chuck #

Suitable for thin, small, and medium workpieces in light-duty machining.

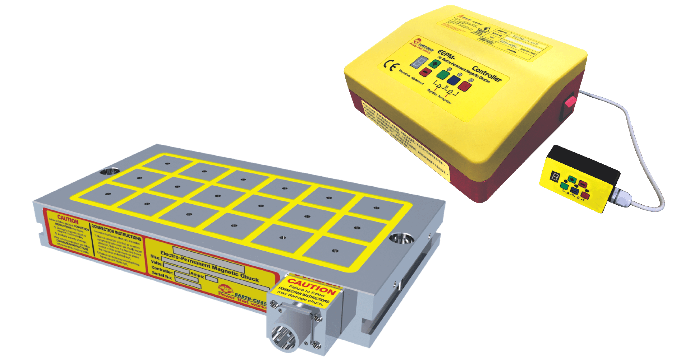

EEPM-B Series: Electro-Permanent Magnetic Chuck #

Designed for small and medium workpiece machining.

EEPM-C Series: Electro-Permanent Magnetic Chuck (Connection Type) #

Suitable for use with large vertical lathes, double column machining centers, and CNC machining centers.

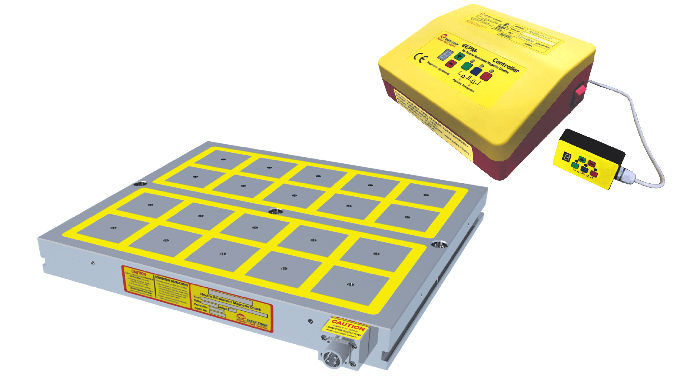

EEPM-D Series: Electro-Permanent Magnetic Chuck #

Engineered for medium and large workpieces in heavy-duty machining.

EEPM-E Series: Electro-Permanent Magnetic Chuck #

Optimized for large and high-thickness workpieces.

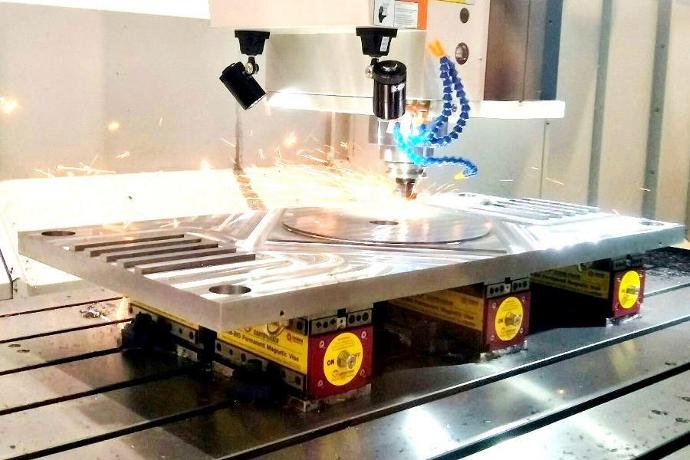

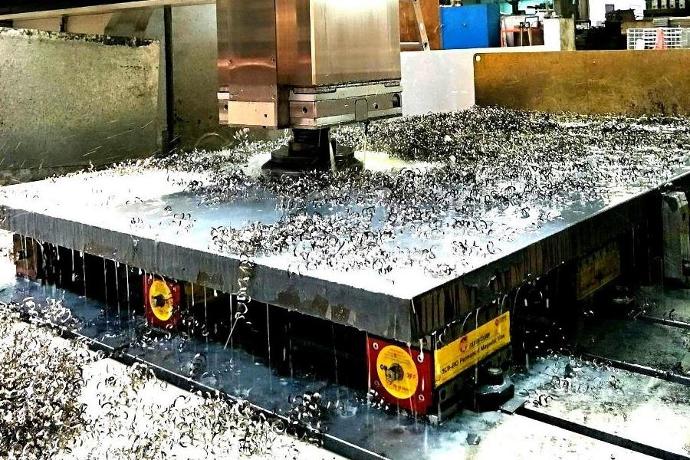

Permanent Magnetic Clamping Block ECB Series #

The ECB Series introduces a new approach to clamping for metalworking on CNC machining centers and milling machines, enabling quick and flexible workpiece clamping.

- Flexible Setup: Position, number, and distance of magnetic clamping blocks can be freely adjusted to match workpiece size.

- Induction Soft Block: The included changeable induction soft block can be machined for 100% accuracy and allows direct cutting, drilling, tapping, and slotting during workpiece machining. Users can customize the block as needed.

- Two Machining Circles: Enables efficient completion of workpiece machining in two cycles, improving productivity and accuracy.

Ready to optimize your projects with magnetic technologies?

Get In Touch Today!