Magnetic Clamping Systems for Enhanced Automation #

Magnetic chucks play a pivotal role in modern automated production, offering fast, reliable, and uniform workpiece holding without the risk of deformation. By eliminating the need for mechanical clamps, these systems not only reduce setup time but also improve machining accuracy and safety. They are particularly well-suited for ferrous materials and are widely used in CNC, grinding, and milling applications to boost productivity.

Key Magnetic Clamping Solutions #

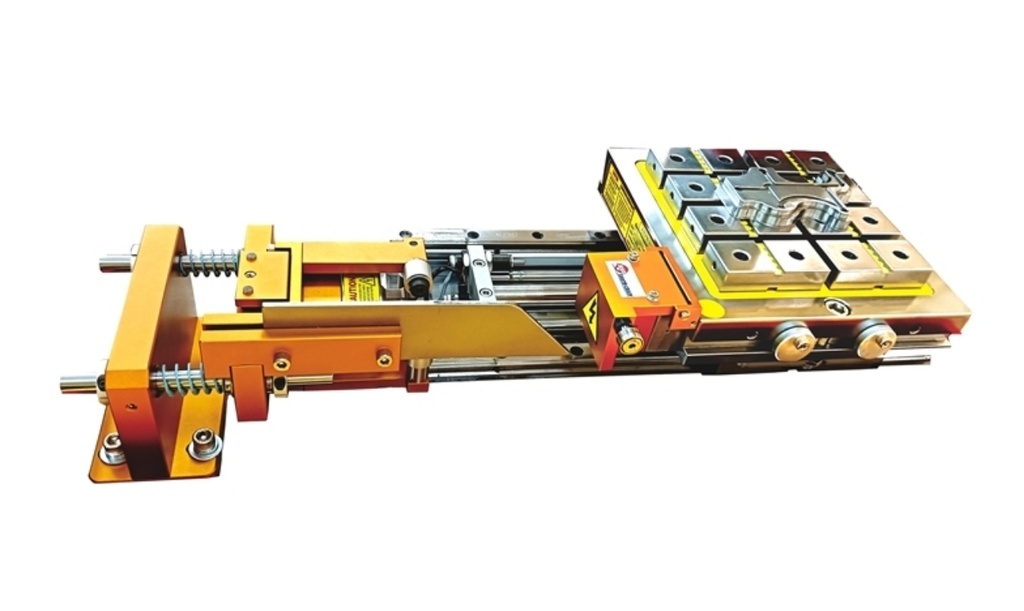

EEPM-V Series

EEPM-V Series

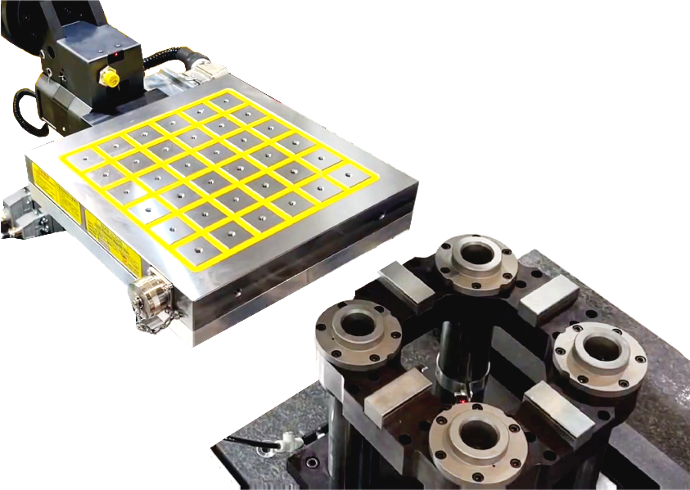

EEPM-SAC Series

EEPM-SAC Series

Zero Point workholding

Zero Point workholding

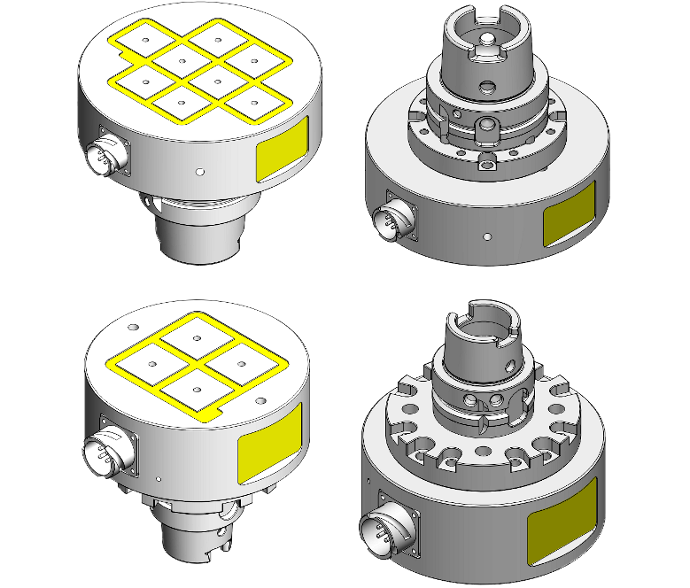

EEPM-CIRTA Series

EEPM-CIRTA Series

PECM SERIES

PECM SERIES

ECM SERIES

ECM SERIES

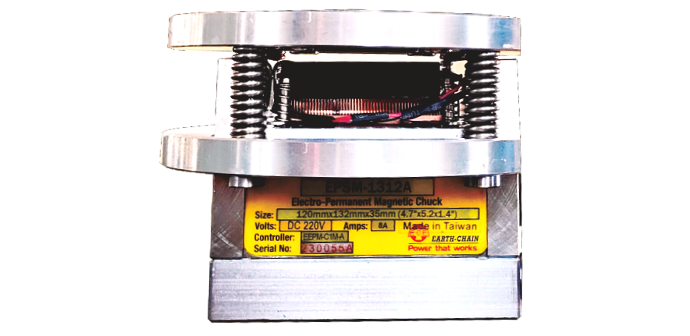

EPSM Series

EPSM Series

EPSM-SC Series

EPSM-SC Series

ECB Series

ECB Series

Product Highlights #

- EEPM-V Series: Customized magnetic chuck with multi-zone cooperative control for flexible workholding.

- EEPM-SAC Series: Features an automated self-aligning connection system for seamless integration.

- Zero Point Workholding: Offers automatic zero point positioning and magnetic chuck changing for rapid setups.

- EEPM-CIRTA Series: Tool arbor type quick changing magnetic chuck system for efficient tool changes.

- PECM SERIES: Electro permanent magnet for robust and energy-efficient clamping.

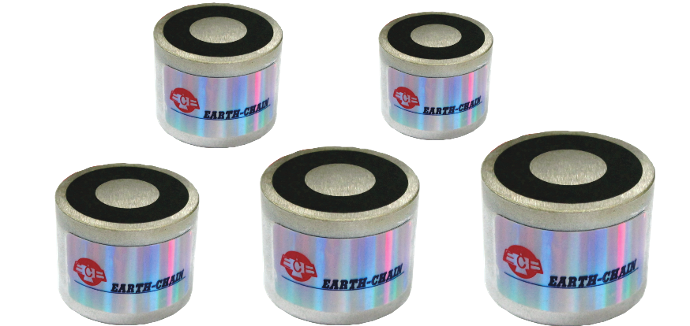

- ECM SERIES: Compact small electromagnet for specialized applications.

- EPSM Series: Combines electromagnet and permanent magnet technologies.

- EPSM-SC Series: Magnetic system with silicon cooling chip for enhanced thermal management.

- ECB Series: Magnetic clamping block with automatic switching system for streamlined operations.

Benefits of Magnetic Clamping in Automation #

- Reduced Setup Time: Quick and easy workpiece positioning accelerates production cycles.

- Uniform Clamping Force: Ensures consistent holding without deforming the workpiece.

- Enhanced Safety: Eliminates the need for manual clamps, reducing operator risk.

- Improved Machining Accuracy: Stable and precise workholding supports high-quality results.

- Increased Productivity: Ideal for high-throughput CNC, grinding, and milling environments.

Ready to Optimize Your Production? #

Explore More:

- Selected Products

- Magnetic Workholding

- Customized Magnetic Chuck

- Electro Permanent Magnetic Chuck

- Optional Accessories - EEPM Series

- Magnetic Clamping Block

- Magnetic Surface Grinder

- Quick Mold Change Systems

- Linear Grinding

- Battery Powered Lifting Magnets

- Permanent Lifting Magnet

- Drill Grinder / End Mill Re-Sharpener

- Universal Magnetic Stand

- Magnetic Tools

- Magnetic Polishing Machine

Practical Applications:

- Automated Production Applications

- Precision Grinding Applications

- Vertical Machining Applications

- Horizontal Machining Applications

- Double Column Machining Applications

- Customization Applications

- Round Workpieces Machining Applications

- 4 Axis Machining Applications

- Linear Guideway & Sliding Block Machining Applications

- Quick Mold Changing Applications

- Rail Machining Applications

- Multi-Pallet Machining Applications

Contact Information