Unlocking Efficiency and Precision with Electro Permanent Magnetic Chucks #

Electro Permanent Magnetic Chucks (EEPM) are engineered to deliver robust, stable, and energy-efficient workpiece clamping for a wide spectrum of machining operations. By harnessing strong permanent magnetic force, these chucks ensure secure holding of workpieces, minimizing movement and vibration during processing. This not only enhances safety but also contributes to significant energy savings.

Key Advantages of EEPM Technology #

- Stable and Uniform Clamping: The permanent magnetic force provides consistent holding power, reducing the risk of workpiece displacement and cumulative machining errors.

- Energy Efficiency: Once magnetized, EEPM chucks require no continuous power supply, making them both safe and cost-effective.

- Versatile Workpiece Handling: Rapid clamping is possible for workpieces of various shapes and sizes, supporting multi-sided machining such as drilling, tapping, and slot milling in a single setup.

- Enhanced Machining Efficiency: The ability to securely clamp workpieces for multi-process operations streamlines workflows and lowers overall processing costs.

EEPM Series Overview #

A variety of EEPM series are available, each tailored to specific machining requirements and workpiece dimensions:

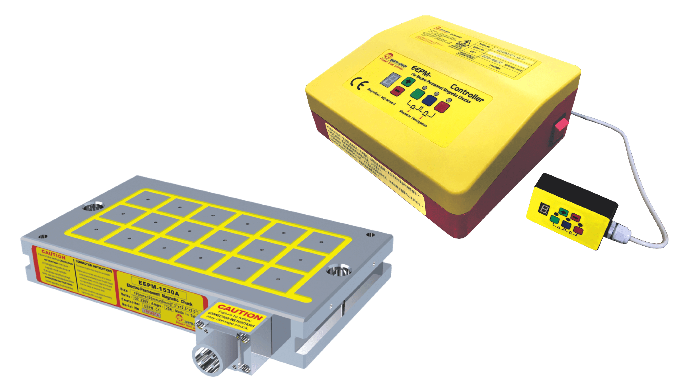

EEPM-A Series

EEPM-A Series

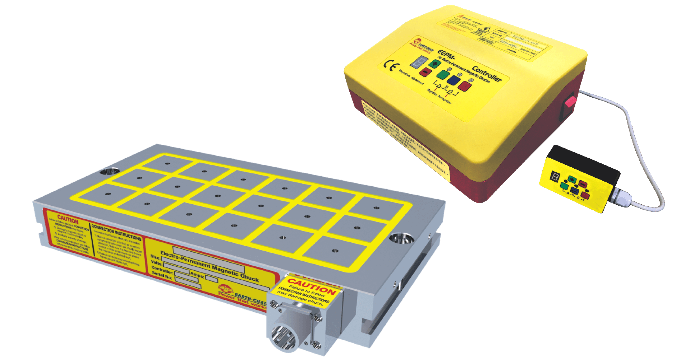

EEPM-B Series

EEPM-B Series

EEPM-C Series

EEPM-C Series

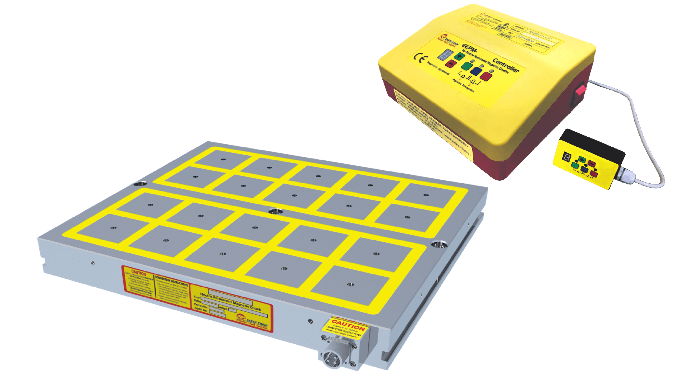

EEPM-D Series

EEPM-D Series

EEPM-E Series

EEPM-E Series

EEPM-C1/C2

EEPM-C1/C2

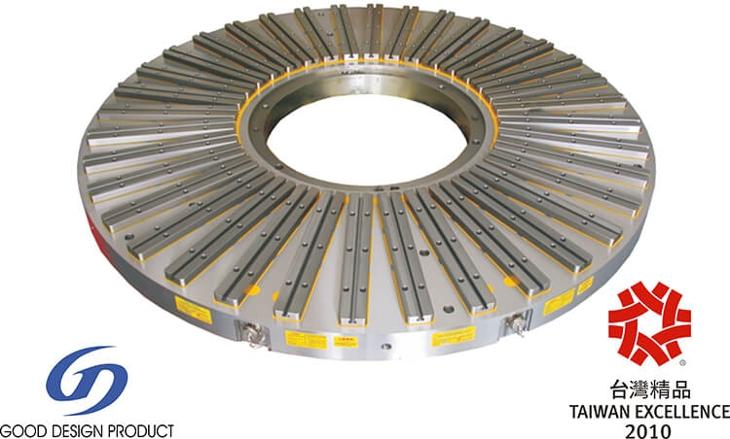

EEPM-CIRA & EEPM-CIR Series

EEPM-CIRA & EEPM-CIR Series

EEPM-CIRSA & EEPM-CIRS Series

EEPM-CIRSA & EEPM-CIRS Series

EEPM-CIT Series

EEPM-CIT Series

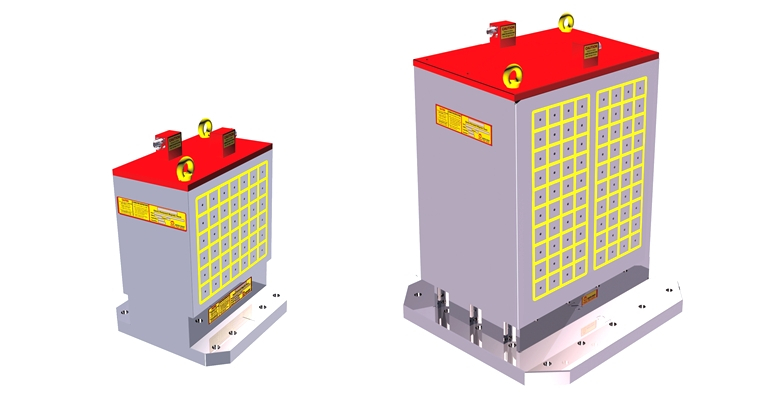

EEPM-V Series

EEPM-V Series

EEPM-SL Series

EEPM-SL Series

EEPM-TA Series

EEPM-TA Series

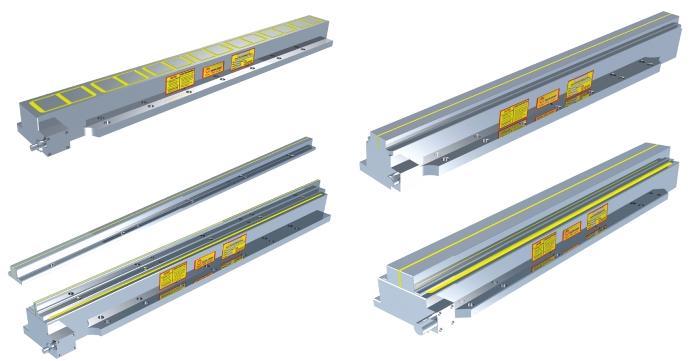

EEPML Series

EEPML Series

Series Applications at a Glance #

- EEPM-A Series: Designed for thin, small, and medium workpieces in light-duty machining.

- EEPM-B Series: Ideal for small and medium workpiece machining.

- EEPM-C Series: Suitable for large vertical lathes, double column machining centers, and CNC machining centers.

- EEPM-D Series: Built for medium and large workpieces in heavy-duty machining environments.

- EEPM-E Series: Optimized for large and high-thickness workpieces.

- EEPM-C1/C2: Optional controllers for precise EEPM chuck control.

- EEPM-CIRA & EEPM-CIR Series: Round magnetic chucks for specialized applications.

- EEPM-CIRSA & EEPM-CIRS Series: Additional round magnetic chuck options.

- EEPM-CIT Series: Compatible with CNC 4-axis index devices.

- EEPM-V Series: Designed for CNC horizontal machining centers.

- EEPM-SL Series: Versatile for all workpiece sizes, can be combined with mechanical clamping tools.

- EEPM-TA Series: For large workpieces, used with mechanical clamping for heavy-duty machining.

- EEPML Series: Tailored for linear grinding applications.

Practical Applications #

EEPM chucks are widely used across various machining scenarios, including:

- Automated production

- Precision grinding

- Vertical, horizontal, and double column machining

- Customization and round workpiece machining

- 4-axis machining

- Linear guideway and sliding block machining

- Quick mold changing

- Rail and multi-pallet machining

For more details on specific applications, visit the Practical Case section.

Connect with Us #

Ready to enhance your machining projects with advanced magnetic technologies? Get In Touch Today!

Contact Information: