Advanced Magnetic Solutions for Linear Grinding Applications #

Electro-permanent magnetic chucks offer a reliable and efficient approach to workpiece clamping in linear grinding processes. These chucks are engineered to quickly magnetize or demagnetize, significantly reducing setup times and streamlining workflow. The internal permanent magnets ensure a stable and consistent magnetic force, which is crucial for maintaining precise workpiece positioning and minimizing the risk of displacement or vibration during grinding operations.

A key advantage of this technology is the even distribution of magnetic force across the chuck surface. This uniformity directly contributes to improved grinding flatness and higher accuracy, making it especially suitable for applications that demand tight tolerances and consistent results.

The compact and robust construction of electro-permanent magnetic chucks supports long-term, continuous production. This durability not only reduces maintenance requirements but also lowers energy consumption, contributing to cost savings and operational efficiency. Enhanced safety features further support a secure working environment.

These characteristics make electro-permanent magnetic chucks an ideal clamping solution for high-precision rail grinding and other demanding linear grinding tasks.

Key Features #

- Rapid magnetization and demagnetization for efficient workflow

- Stable, long-term magnetic force for precise workpiece fixation

- Even magnetic force distribution for superior grinding flatness and accuracy

- Compact, durable design for extended production use

- Reduced energy consumption and maintenance costs

- Enhanced safety and processing efficiency

For those seeking to optimize their linear grinding operations with advanced magnetic technologies, the EEPML Series and related solutions provide a dependable and effective choice.

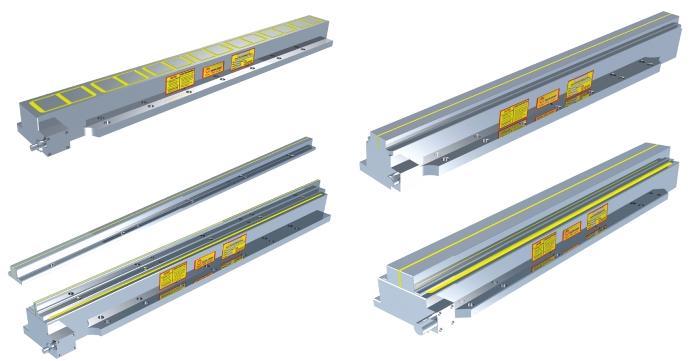

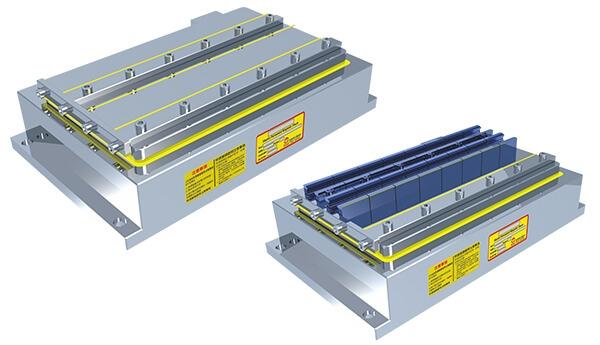

EEPML Series

EEPML Series EEPML-3045

EEPML-3045