Elevating Machining Performance with Magnetic Workholding #

Magnetic workholding systems are transforming the way machining operations are performed, offering a blend of high precision, efficiency, and adaptability. By utilizing robust permanent or electro-permanent magnets, these systems deliver a uniform clamping force that secures workpieces without causing deformation. This technology enables five-sided machining, reduces setup times, and improves surface finishes, all while minimizing vibration and extending tool life. As a result, productivity is significantly enhanced across CNC milling, grinding, and turning applications.

Key Benefits of Magnetic Workholding #

- Uniform Clamping Force: Ensures stable and distortion-free workpiece holding.

- Five-Sided Machining: Facilitates comprehensive access for complex operations.

- Reduced Setup Time: Streamlines the preparation process for increased throughput.

- Enhanced Surface Finish: Minimizes vibration, leading to superior results and longer tool life.

- Versatile Applications: Ideal for a wide range of machining tasks, from small components to large-scale workpieces.

Product Portfolio #

EEPM-V Series

EEPM-V SeriesCustomized Magnetic Chuck with Multi-zone Cooperative Control

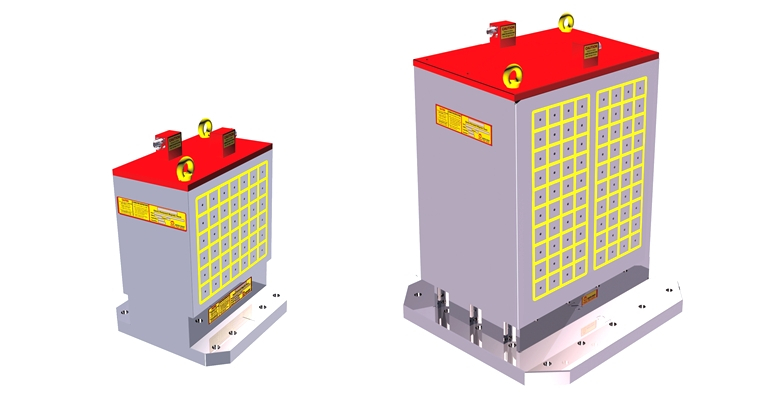

EEPM-B Series

EEPM-B SeriesFor Small and Medium Workpiece Machining

EEPM-C Series

EEPM-C SeriesFor Large Vertical Lathe, Double Column, and CNC Machining Centers

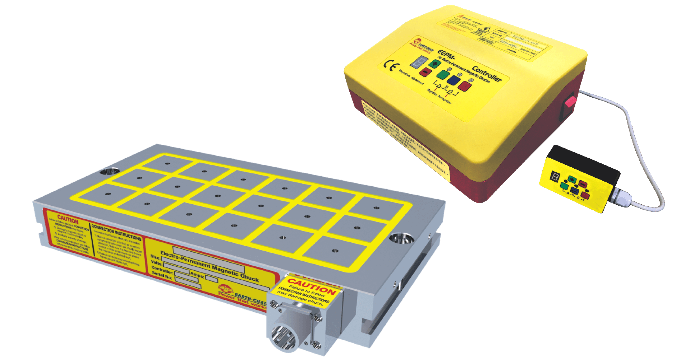

ECB Series

ECB SeriesMagnetic Clamping Block

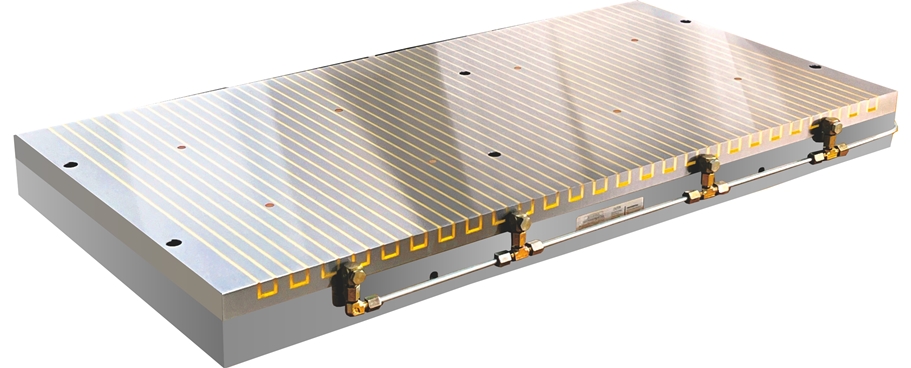

EEPG Series

EEPG SeriesSurface Grinder Magnetic Bed, Table

EEPM-V Series

EEPM-V SeriesFor CNC Horizontal Machining Centers

EEPM-CIT Series

EEPM-CIT SeriesFor Use with CNC 4 Axis Index Devices

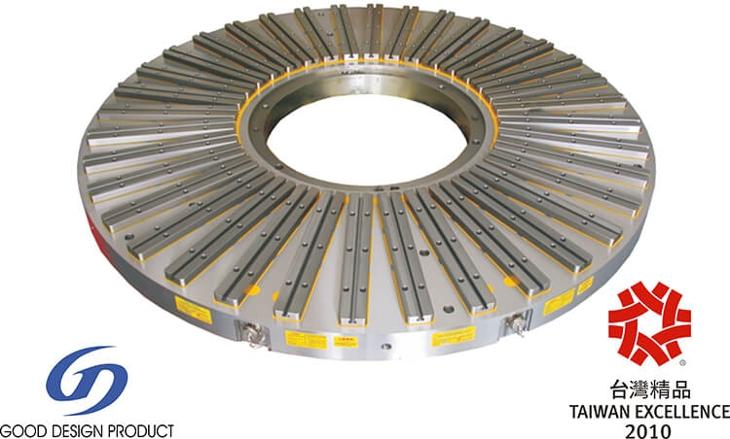

EEPM-CIRA & EEPM-CIR Series

EEPM-CIRA & EEPM-CIR SeriesRound Magnetic Chuck

EEPM-CIRSA & EEPM-CIRS Series

EEPM-CIRSA & EEPM-CIRS SeriesRound Magnetic Chuck

EEPM-PIM Series

EEPM-PIM SeriesQuick Mold Change Systems

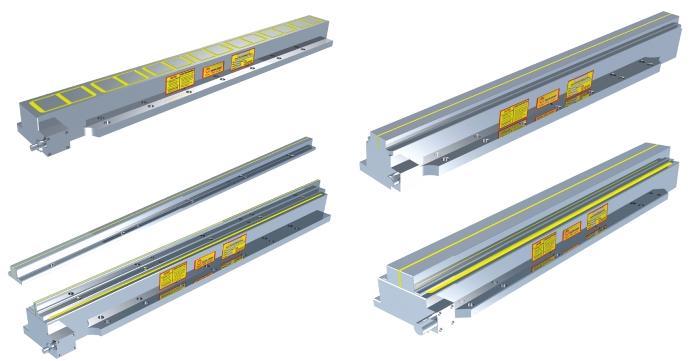

EEPML Series

EEPML SeriesLinear Grinding

Applications #

Magnetic workholding systems are suitable for a variety of machining environments, including:

- CNC milling and turning

- Surface and precision grinding

- Vertical, horizontal, and double column machining centers

- 4-axis machining and round workpiece applications

- Quick mold changing and linear guideway machining

Connect with Us #

Ready to enhance your machining projects with advanced magnetic technologies? Get In Touch Today!

Contact Information